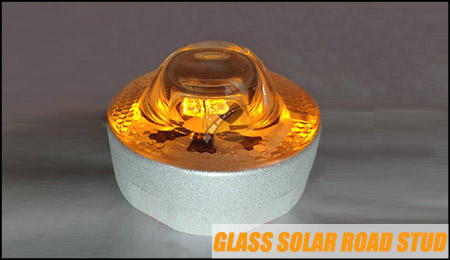

360 degree glass road stud, also known as fully toughened glass solar road stud.

Basic materials and reflection principle: the toughened glass road stud uses optical grade glass, and uses the principle of convex lens and concave mirror to form an optical system, which can reflect the head light of vehicles and play a good guiding effect at night.

The toughened glass solar road stud is super tempered glass after special toughening treatment. The pressure resistance of all toughened glass road stud can be as high as 20 tons, with good impact resistance and long service life. If the toughened glass solar road stud is broken, it will be granular, similar to the small stone (this is the characteristics of toughened glass), and it will not affect the driving safety.

360 degree glass solar road stud has strong surface hardness and wear resistance. The protruding part of 360 degree glass road stud is semicircular. Without edges and corners, it contributes to drive smoothly The vehicle will have vibration prompt function produced by glass solar road stud when driving through the lane at high speed.

Multiple contact wear does not affect the reflective effect so 360 degree solar glass road stud can use for a long time. After grinding and polishing in the production process, the surface finish reaches qualified optical grade, with self-cleaning and cleaning functions, no dust, no sediment collection. So it also need no cleaning.

Solar road studs provide most effective night guidance even under the most adverse weather conditions. Solar road studs are available in different sizes to delineate both the carriage way at the center and at the edges of roads. The special material of 360 degree glass solar road stud composition enables the studs to bear severe impacts.