2024 Plastic Solar Studs On Discount Parking Lot

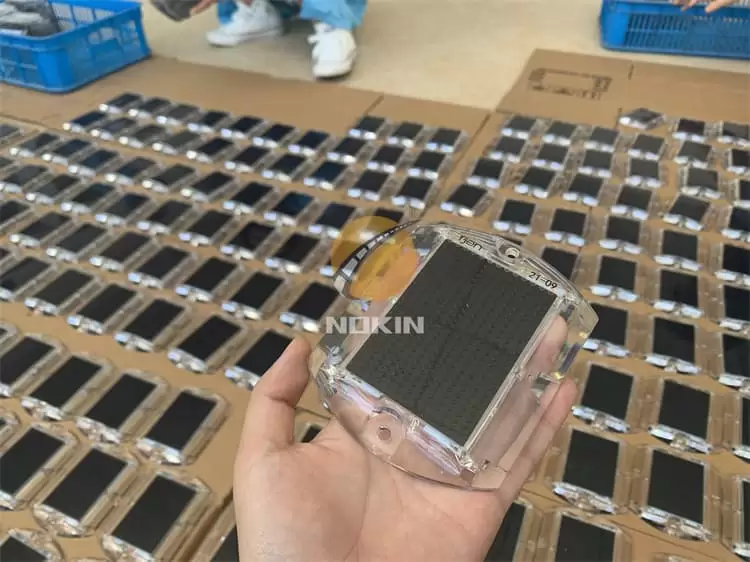

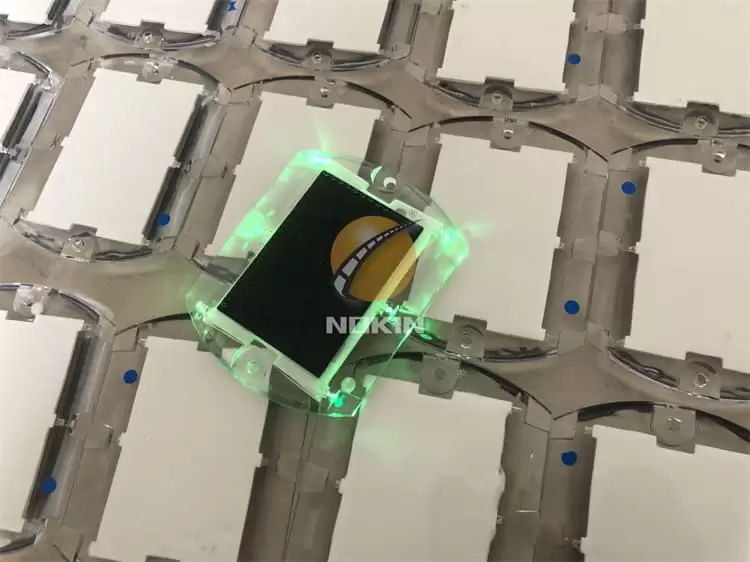

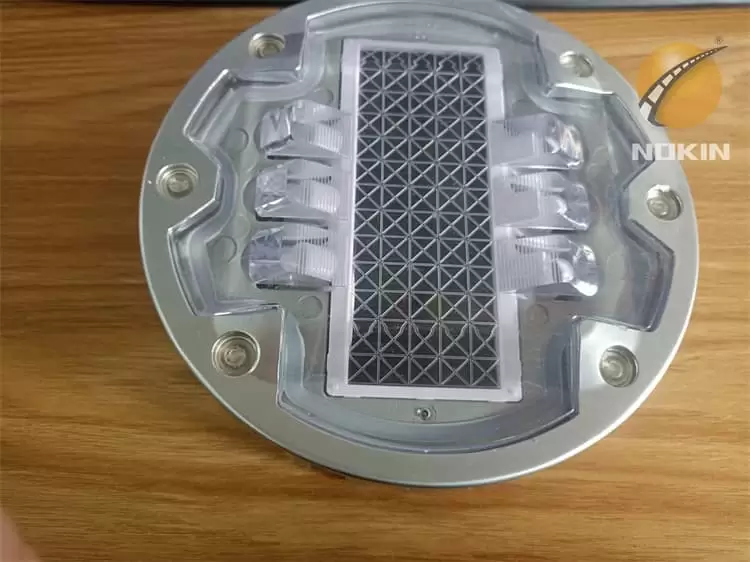

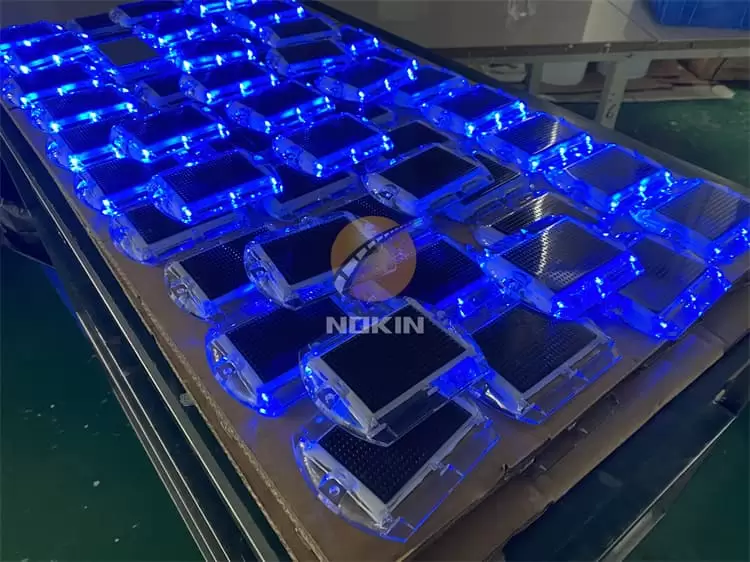

Solar road studs serve as indispensable elements of road safety infrastructure, guiding drivers with illuminated markers even in low-light or adverse weather conditions. Among the key features ensuring their reliability and longevity, waterproof performance stands out as crucial. In this article, we explore why waterproofing is essential for solar road studs, examining its significance in maintaining functionality and durability, ultimately contributing to safer roadways.

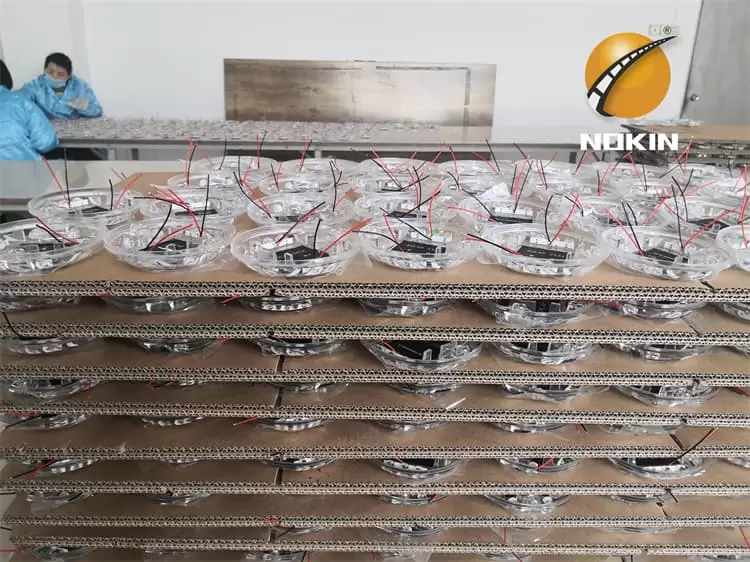

Investing in solar road studs with robust waterproof performance offers long-term cost savings for transportation authorities and municipalities. Waterproof construction materials and design features minimize the need for frequent maintenance, repairs, and replacements, reducing lifecycle costs associated with road safety infrastructure. Additionally, reliable waterproofing ensures uninterrupted operation and extended service life of solar road studs, maximizing return on investment and promoting sustainable and cost-effective road safety solutions.

The waterproof performance of solar road studs is integral to their functionality, durability, and effectiveness in enhancing road safety. By effectively sealing internal components and protecting against moisture ingress, solar road studs can withstand a range of weather conditions and environmental challenges. Transportation authorities, manufacturers, and stakeholders must prioritize waterproofing standards and testing protocols to ensure the reliability, longevity, and compliance of solar road studs, ultimately contributing to safer and more resilient roadways for all.