Content

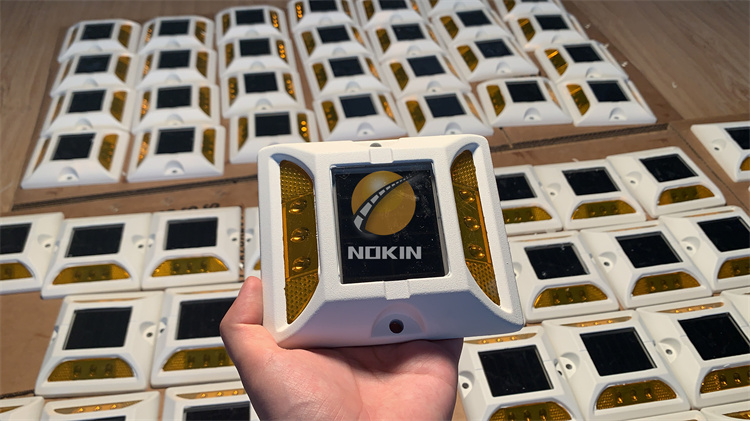

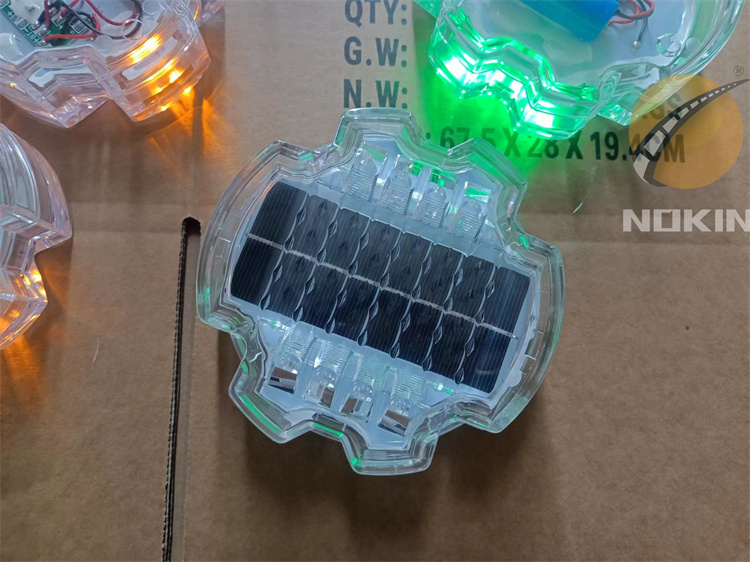

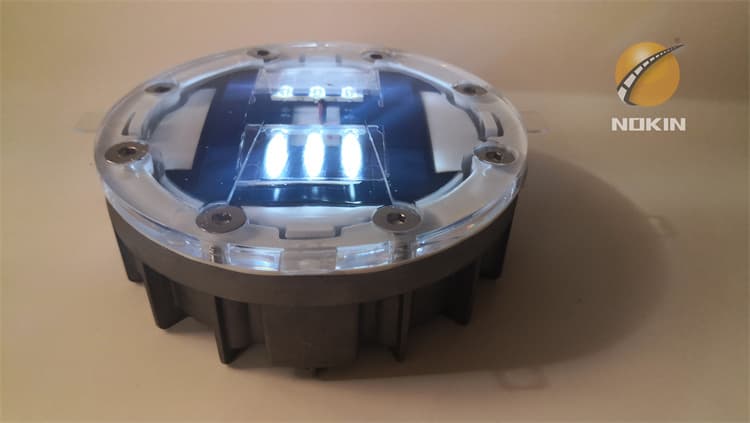

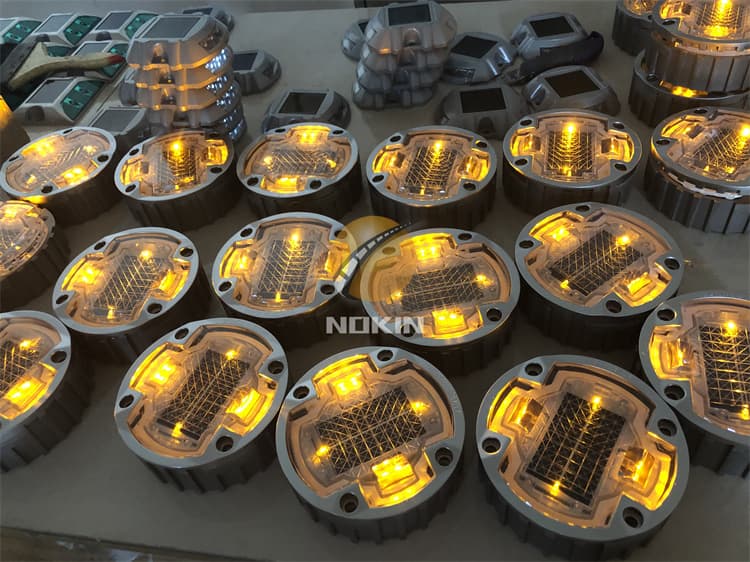

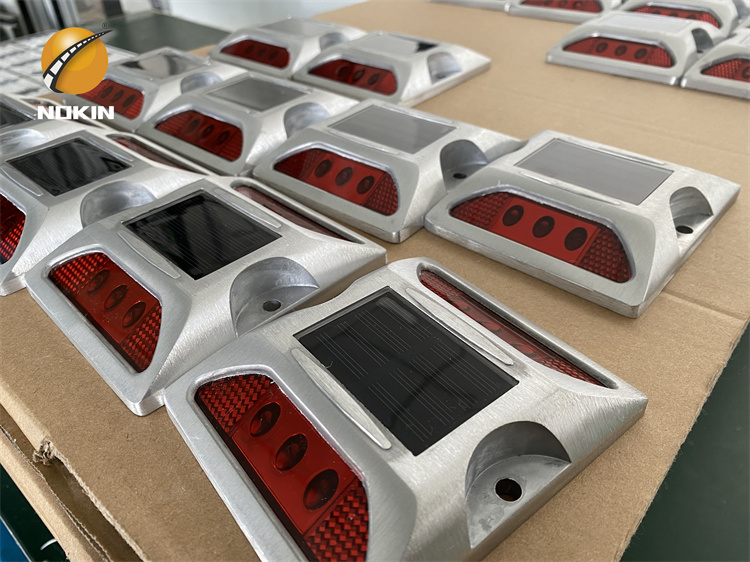

The solar road studs can help to reduce accidents at the regional rail crossing, and intersection and provide guidance and hazard warnings

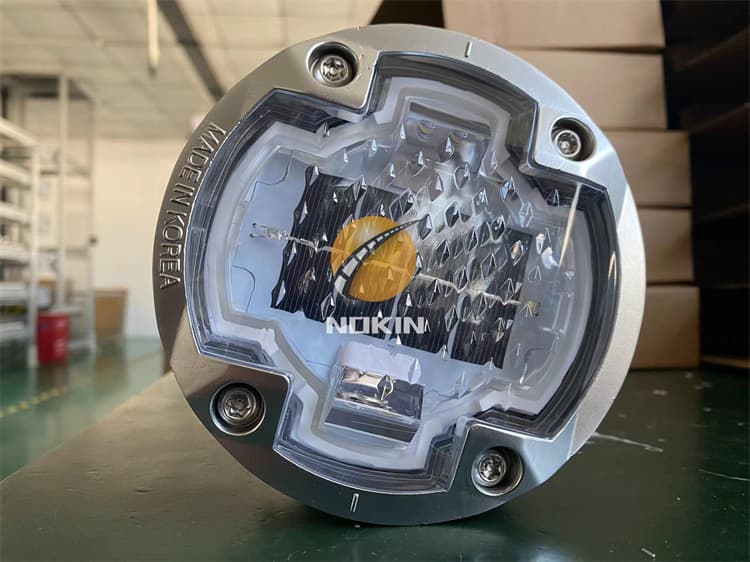

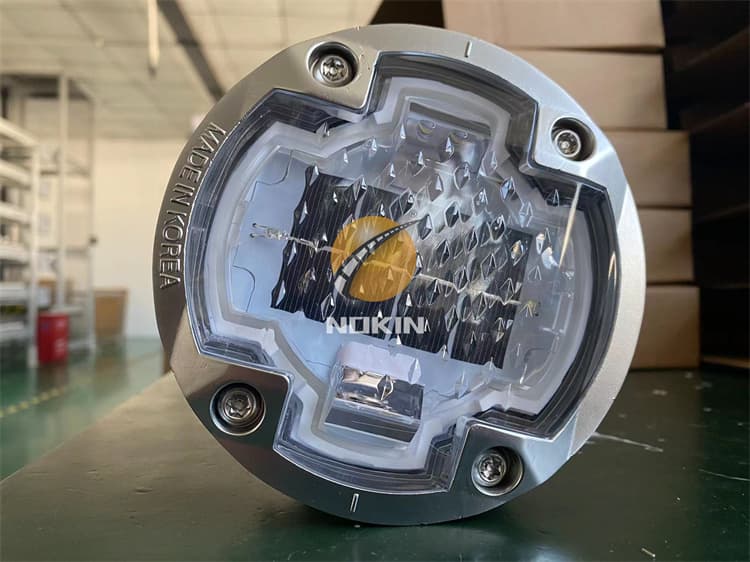

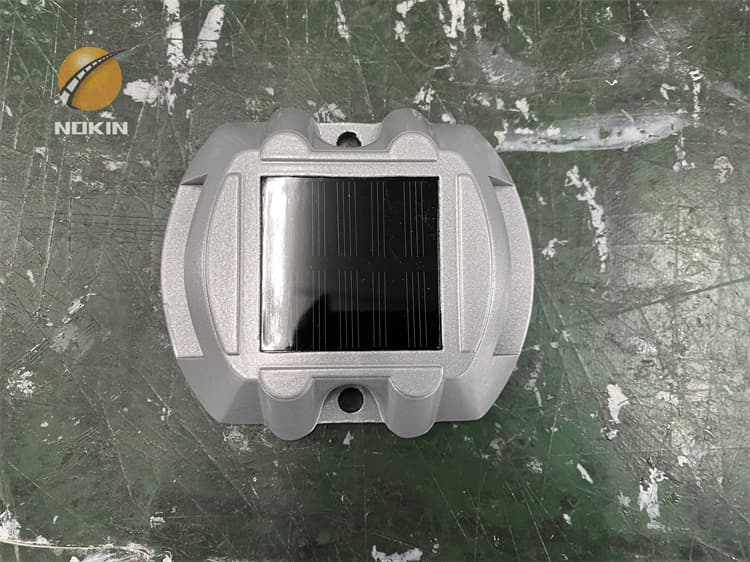

to drivers in darkness and bad weather. The solar studs could automatically charge during the day and flash at night automatically. Flicker mode can discharge for more than 12 days after absorbing enough sunlight. The solar system of aluminum road studs is conducive to reducing environmental impact and saving costs. With more than 21 years of factory experience, cat eye road stud produced by our company’s own competitive aluminum road stud price offers more choices to the global traffic road safety market and trustworthy partners all over the world.

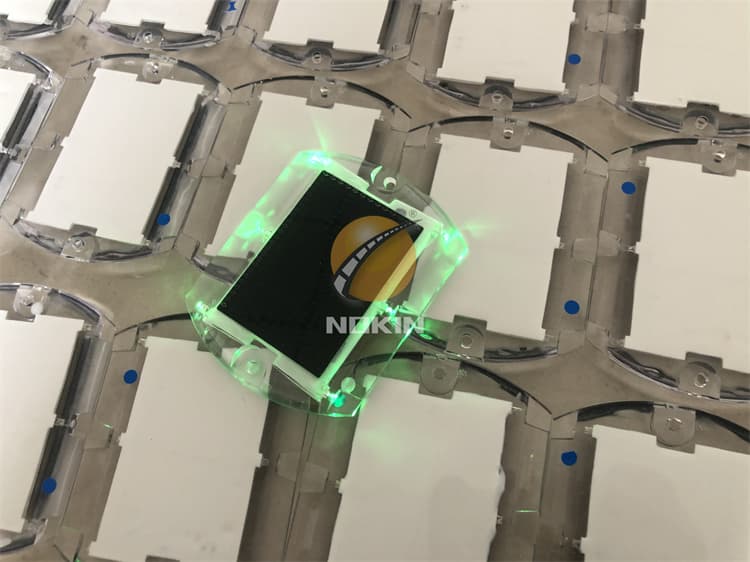

Installation Method Of Raised Solar Road Stud:

Carefully mark the distance between the placement of solar road stud lights. To prevent an adverse effect on the ground, use a proper tool such as Core Drill. Drill 35mm and the depth will be 55mm.

Remove all debris from the installation hole.

Pour epoxy into the holes per the manufacturer’s instruction.

Verify that the installation hole is straight. Verify that the installation hole is large enough to allow the epoxy to surround the solar-led road stud shaft.

Set the lighting surface of the solar road stud to the desired viewing angle. Verify the epoxy is evenly adhering to the installation hole and solar marker shaft. Verify the bottom of the solar road marker is firmly installed on the installation surface allowing for zero surface float; to occur. (space between installation surface and bottom of the solar marker).

After curing the LED solar road stud for 6-8 hours, remove the installation of the isolation facility.

Inquiry

More