Cheap Price LED Road Stud Light For Sale NK-RS-A6

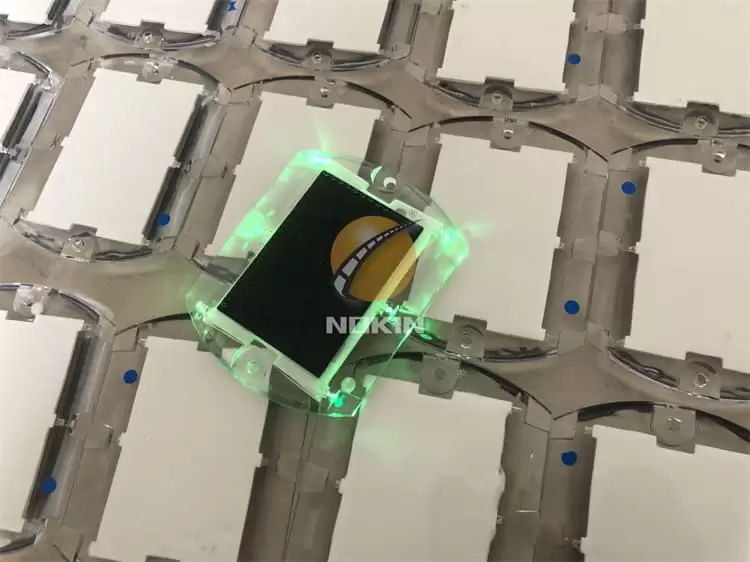

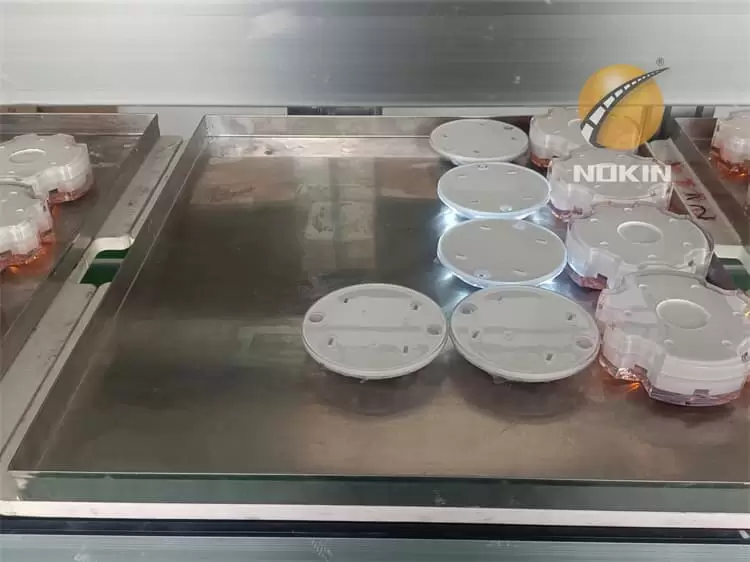

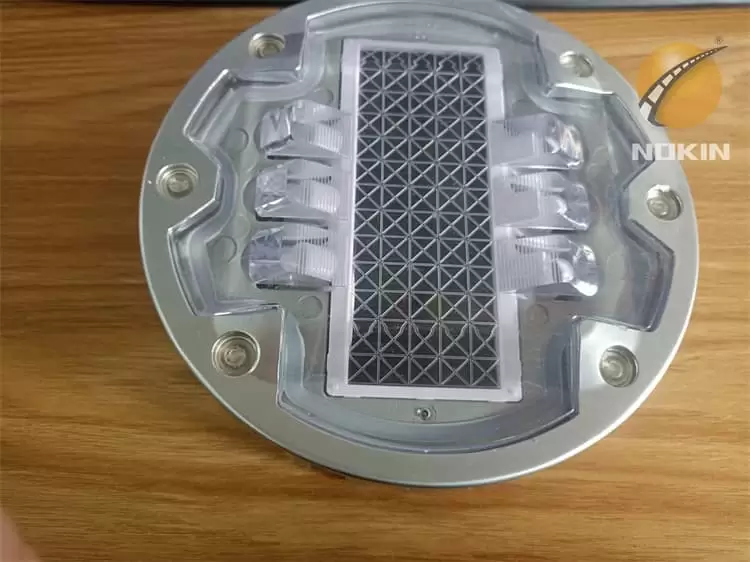

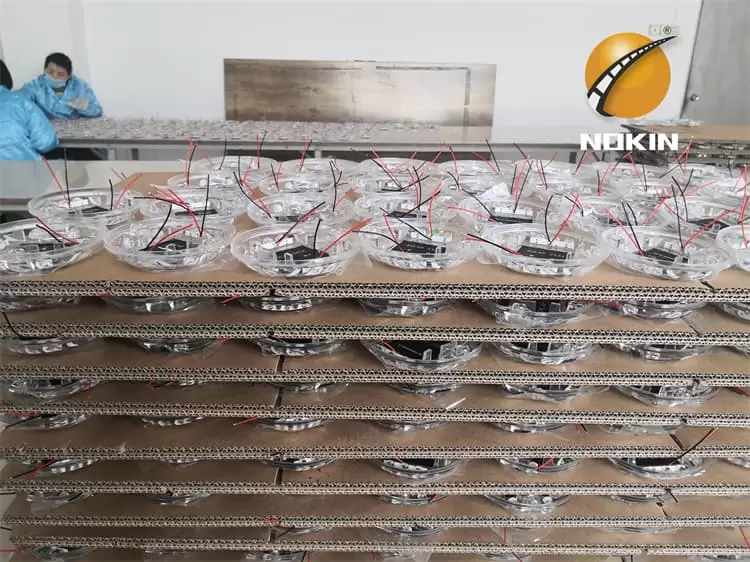

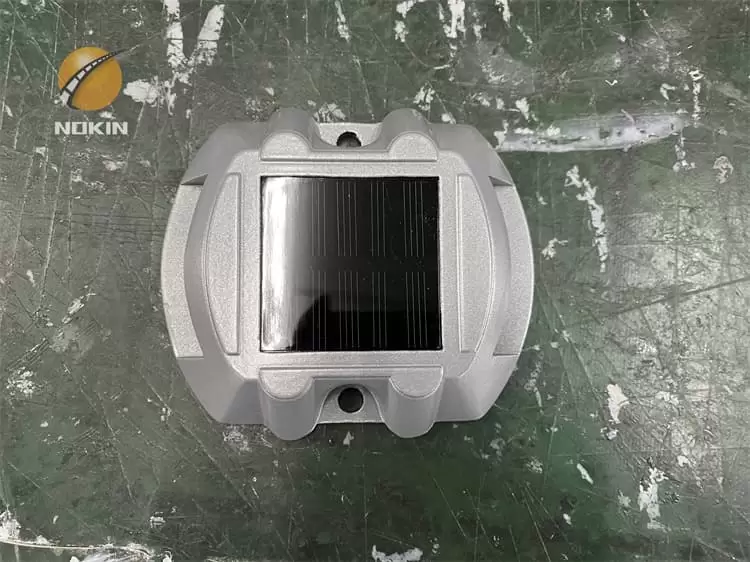

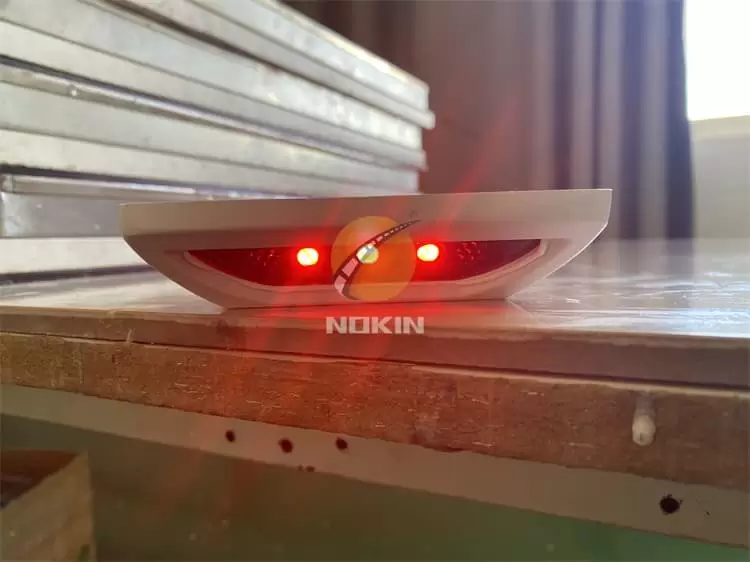

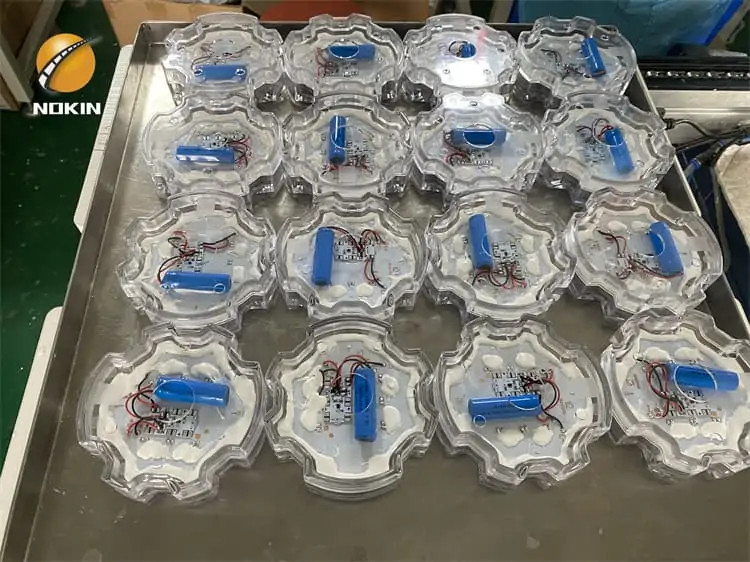

This aluminum solar road stud A6 studs feature a low-profile, raised design that provides a steady or slow-flickering omnidirectional light. Made of high-impact durable engineering-grade polymer and aluminum, the solar road studs provide up to seven days of continuous nighttime illumination in the absence of sunlight.

Solar road studs provide a highly visible profile along a walking or biking path for general route marking and wayfinding. This aluminum solar road stud A6 studs feature a low-profile, raised design that provides a steady or slow-flickering omnidirectional light. Made of high-impact durable engineering-grade polymer and aluminum, the solar road studs provide up to seven days of continuous nighttime illumination in the absence of sunlight.