Constant Bright Cat Eyes Road Stud China

Making solar road studs requires a combination of optical, electronic, and mechanical processes to ensure the quality and functionality of the individual components. The specific production process and steps may vary depending on the manufacturer and product design, and the above steps are for reference only.

Send Inquiry

Quote Online

Share:

Previous:

2023 Ultra Thin Cat Eyes Road Stud Korea

Content

Making solar road studs requires a combination of optical, electronic, and mechanical processes to ensure the quality and functionality of the individual components. The specific production process and steps may vary depending on the manufacturer and product design, and the above steps are for reference only.

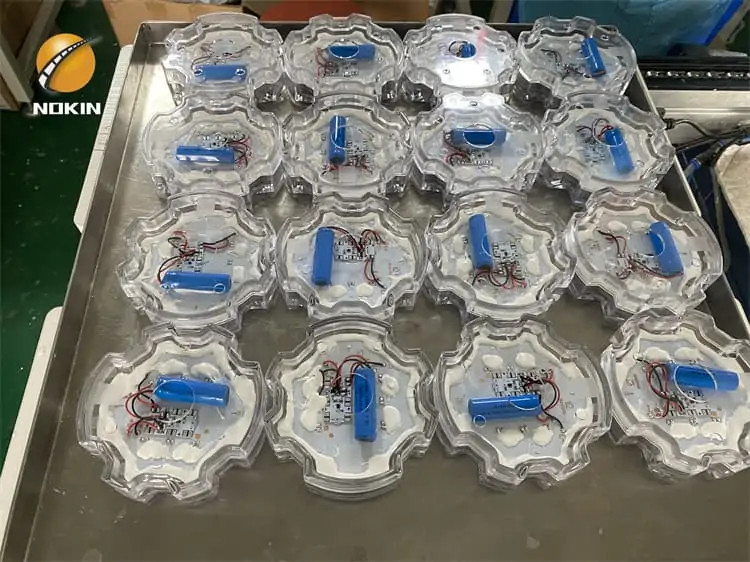

1. Material preparation: Prepare the materials required for making solar road studs, including the road stud body, solar panels, LED lights, reflectors, photosensitive cells, batteries, etc.

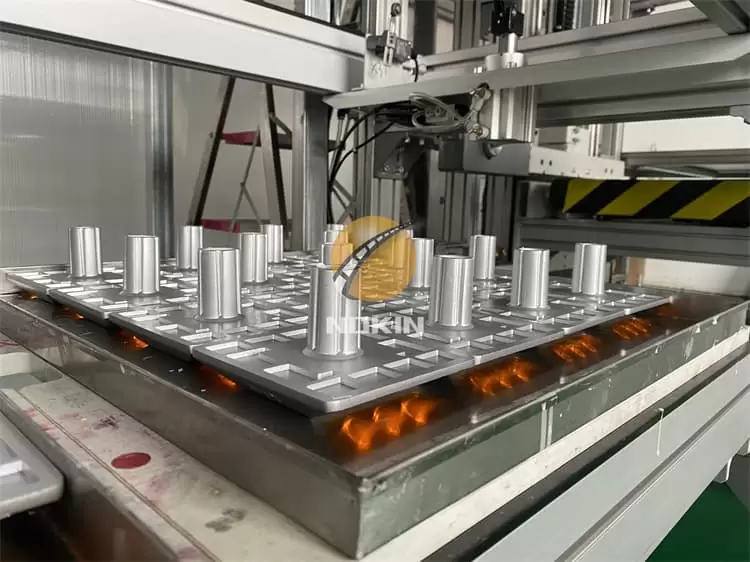

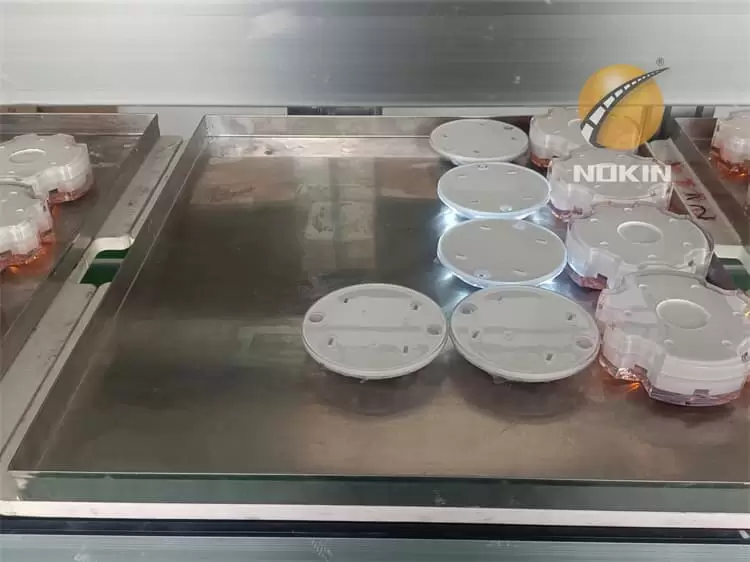

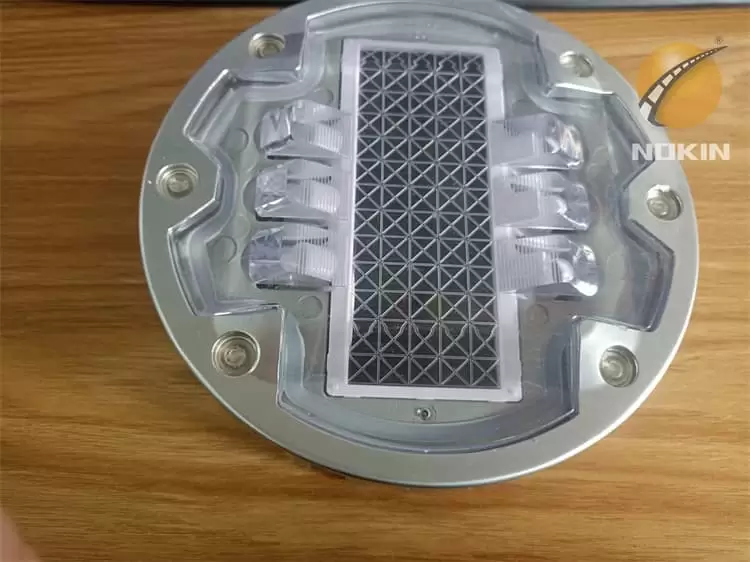

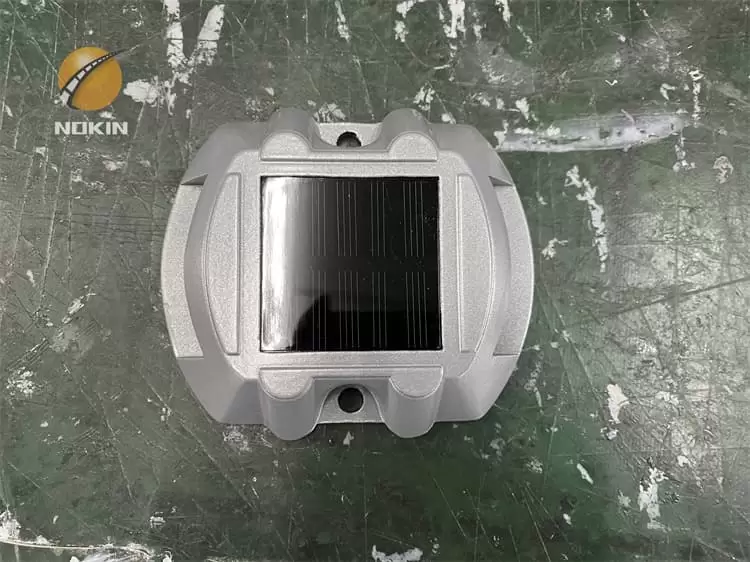

2. Production of road stud body: choose suitable materials (such as plastic or metal) for the production of the road stud body. Processes such as injection molding, die casting or machining can be used to make the material into the shape and size of the spike.

3. Solar Panel Installation: Install solar panels on the top or side of the spike. Solar panels should be able to absorb sunlight and convert it into electricity efficiently. Mount the solar panel on the spikes using glue, screws, or other fixtures.

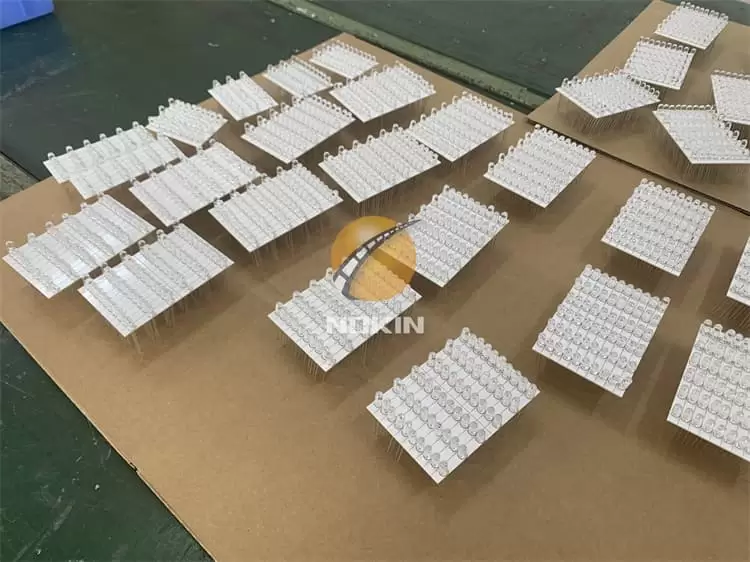

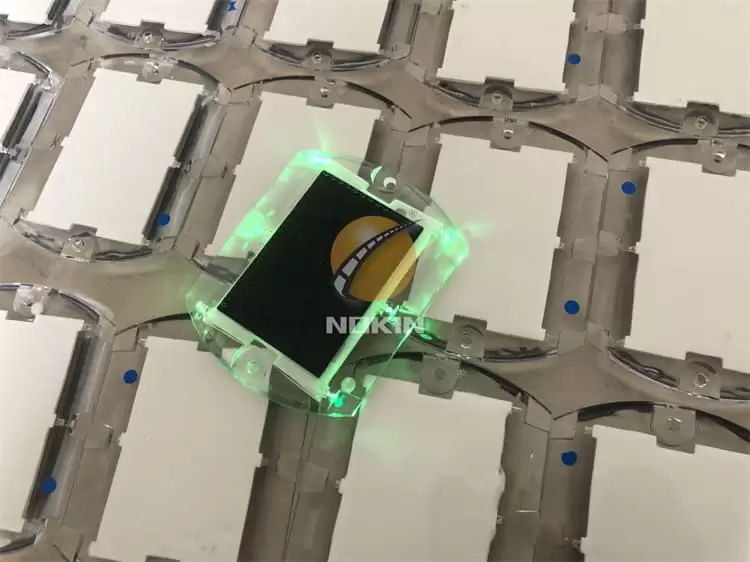

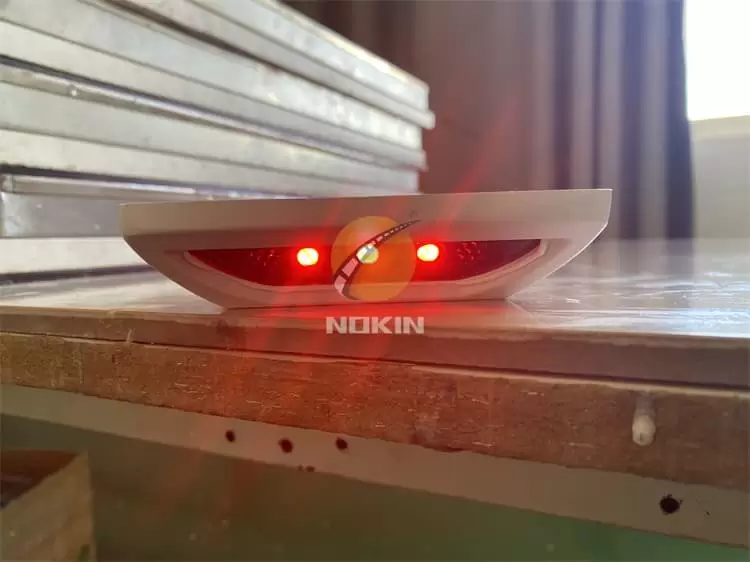

4. Installation of LED lights and reflectors: Install LED lights and glasses on the top or side of the LED solar road stud. LED lights are supposed to provide bright lighting effects and reflective mirrors are used for one-way reflections. The installation position and angle of LED lights and reflector surfaces should be able to maximize the lighting effect.

5.Installation of photosensitive cells and batteries: Install photosensitive cells inside the road stud to sense changes in ambient light. The storage battery is used to store the electric energy converted by the solar panel and supply the lighting energy of the LED lamp when the light is dim.

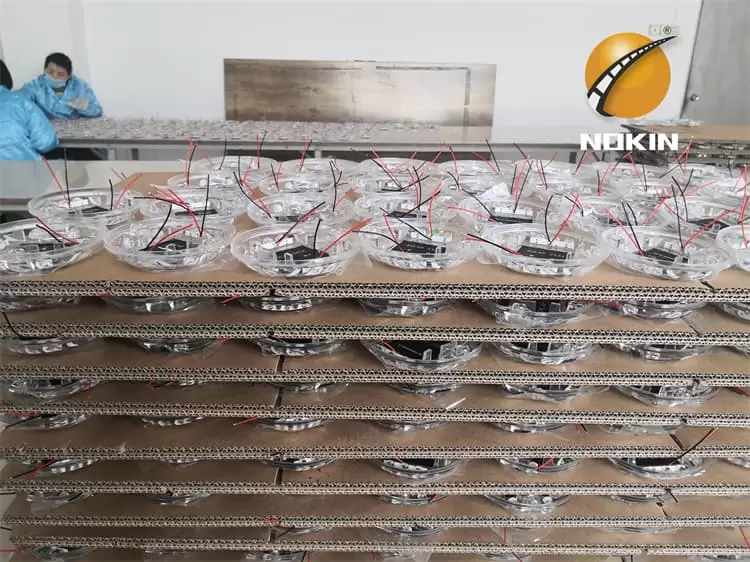

6. Wire connection and packaging: connect the wires between solar panels, LED lights, photosensitive cells, and storage batteries. Ensure the wiring connection is firm and reliable, and take waterproof measures to prevent the road stud from being damaged in a humid environment.

7. Testing and debugging: After the assembly is completed, test and debug the solar road stud to ensure that each component works normally. Tests can include the light conversion efficiency of solar panels, the brightness and reflection of LED lights, and more.

8. Installation and maintenance: Install the finished solar road studs on the road to ensure that they are firmly fixed and meet traffic safety requirements. Regularly check and maintain solar road studs, such as cleaning solar panels, replacing damaged LED lights, etc., to ensure their normal operation and longevity.

Inquiry

More