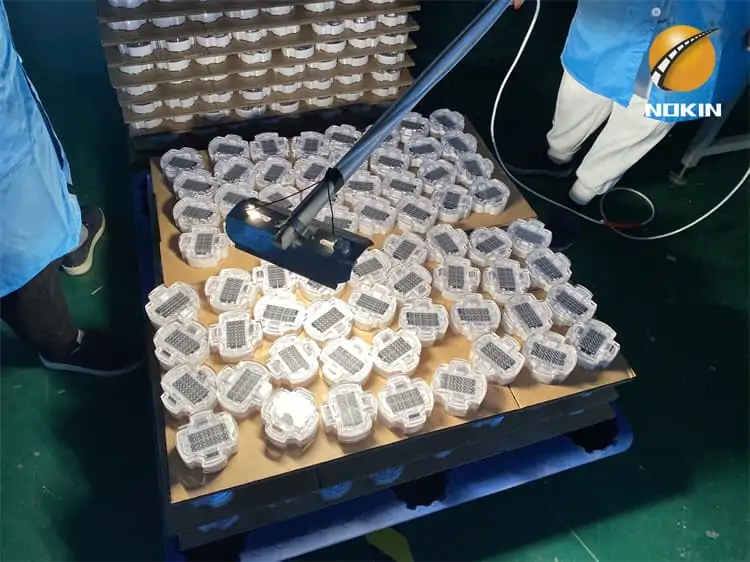

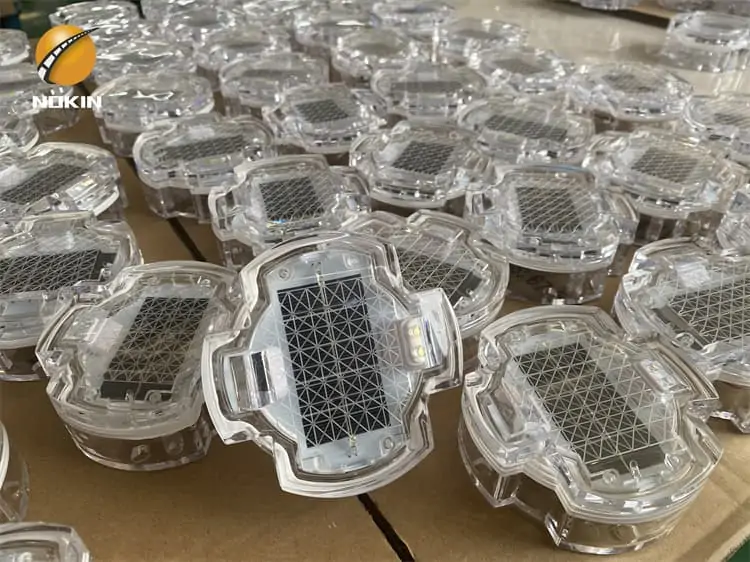

flashing led solar road stud supplier packing

The range of applications for solar road lights extends from simple obstacle marking to complex optical road guidance tasks. Enormous autonomy can be achieved through the conversion of solar energy. Expensive and complex wiring disappears, leaving a clear and defined path.

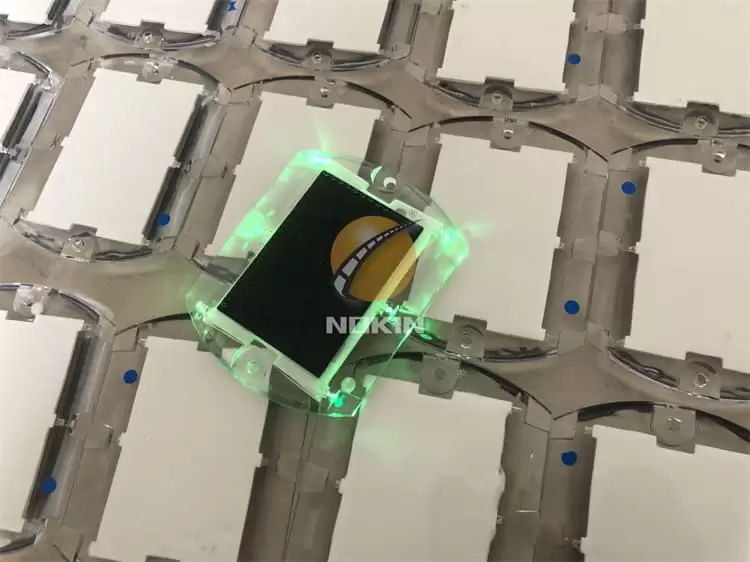

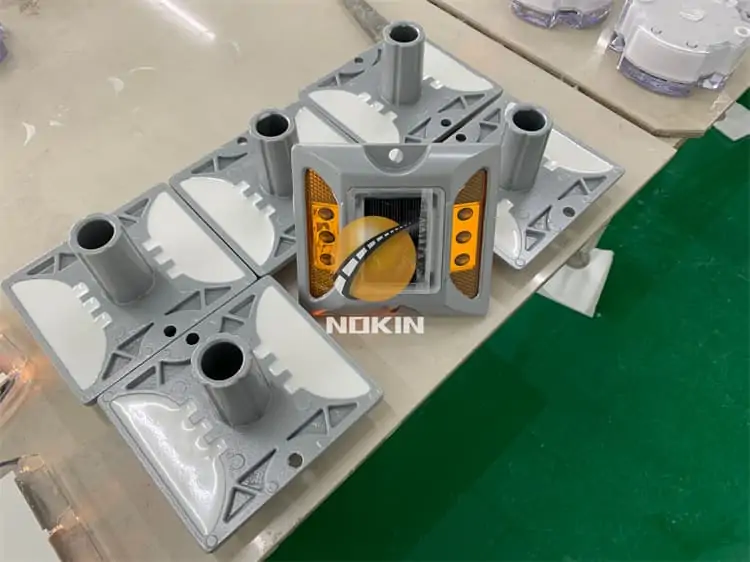

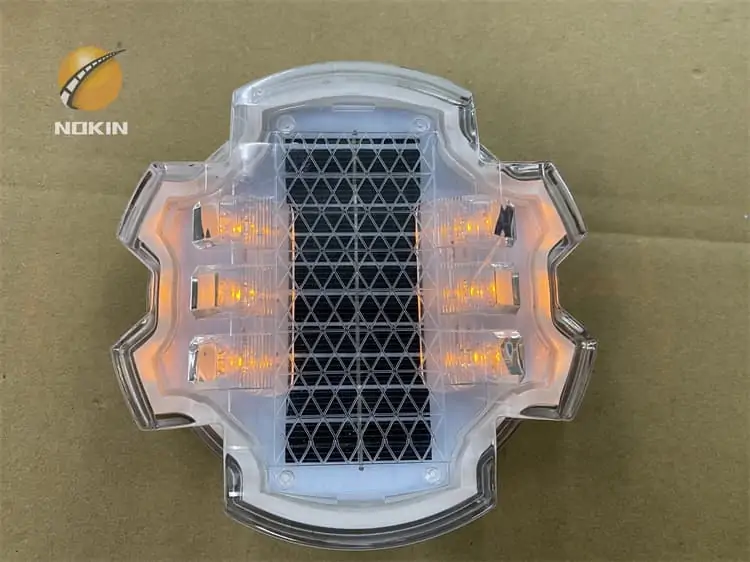

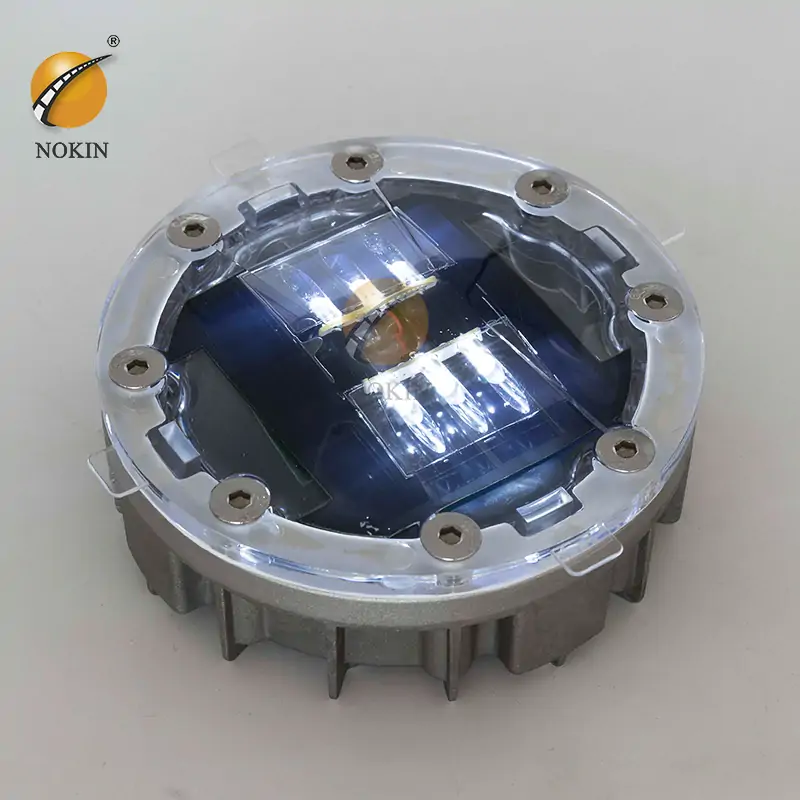

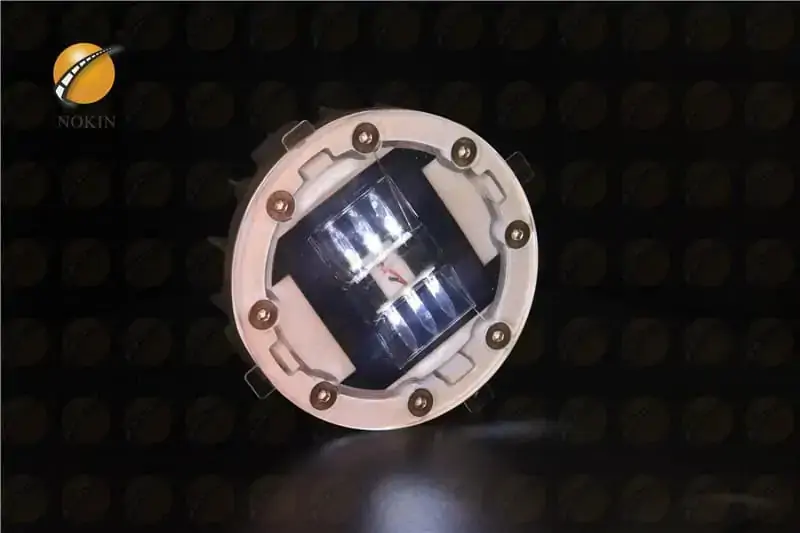

Marketed as solar road studs, the design allows them to be fixed as inserts within a durable cast iron housing, which can then be installed into the road surface. Solar energy resources enhance the benefits of solar LED road studs, such as reducing nighttime accidents, improving visibility, and serving as a sustainable alternative to street lighting. Other advantages include a snap-fit standard cast iron housing unit, which means it can be easily removed and replaced when necessary, such as at the end of its more than eight-year service life. Instead of having to replace the entire housing, only the internal parts need to be replaced. can.

The performance standards for measuring solar studs can be measured from the following aspects:

① Pressure resistance If the solar road makers cannot withstand a certain amount of pressure, it will be easily run over or hit by a car and will not work or be used normally. Therefore, compression resistance is the basic condition for the normal operation of solar road studs. The solar spike itself is an electronic product with complex parts inside. It is indeed not an easy task to provide electronic components with a higher degree of compression performance. Generally speaking, the compression resistance of solar road studs is worse than that of ordinary road studs. Therefore, in recent years, the transportation department has issued new standards for solar road studs.

②Sealing performance If the solar makers are not completely sealed, water will naturally seep into them, causing a short circuit in the circuit, with disastrous consequences. Qualified solar road stud sealing performance is crucial. Methods to improve the sealing performance of solar road studs include: improving the design of the product itself and adopting a separation design. Even if the LED light is broken, water can not enter the inside of the solar road stud. The second method uses strong neutral adhesive materials to prevent water from entering. There are no gaps inside, increasing its tightness.

The range of applications for solar road lights extends from simple obstacle marking to complex optical road guidance tasks. Enormous autonomy can be achieved through the conversion of solar energy. Expensive and complex wiring disappears, leaving a clear and defined path.