New solar stud light for car park price

The stability of solar road studs need to be considered from the solar cells, the temperature of the external environment, the design of electronic circuits, firm welding, etc., in order to extend the service life of solar road studs and provide us with a bright future!

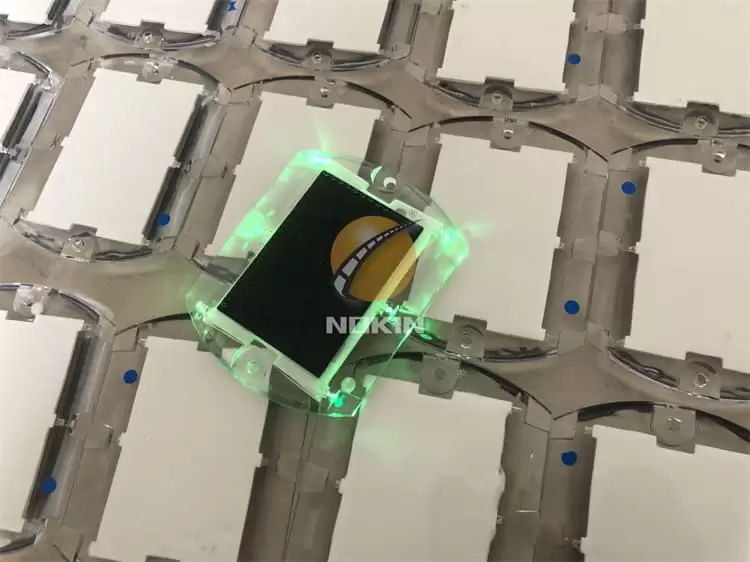

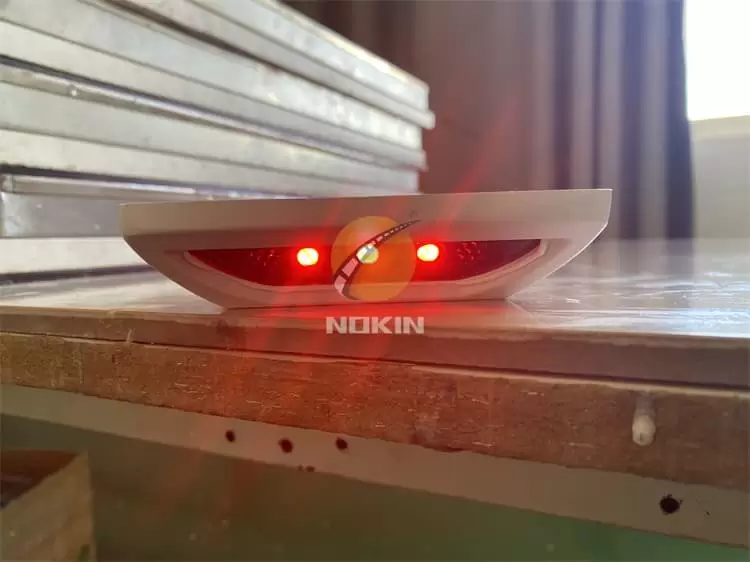

Solar road studs are a product of science and technology. They are a new type of traffic electronic equipment and a road safety sign derived from solar energy. When solar road studs first appeared, they were mainly used for traffic safety facilities, but they are gradually used in courtyards, parks, and other scenes depicting a beautiful landscape, what if solar road spikes can achieve this effect? What I will introduce to you next is that by leveraging the stability of solar road studs, you can maintain continuous development. This is an important performance that needs to be paid attention to.

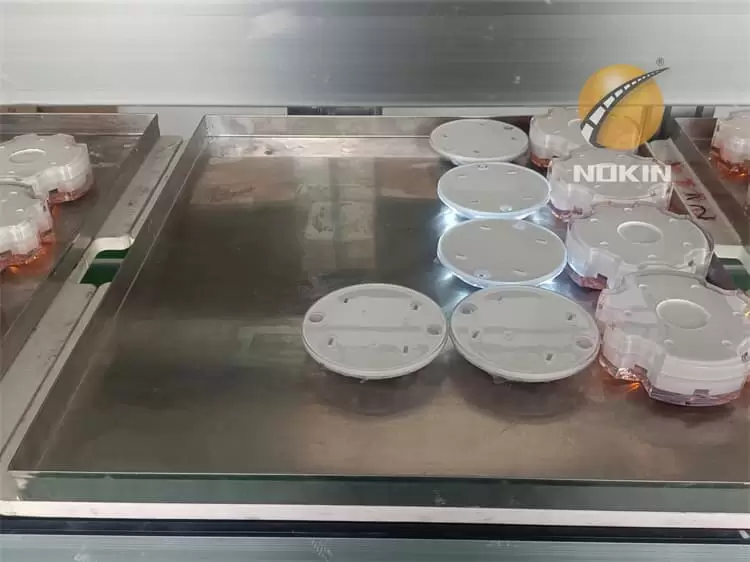

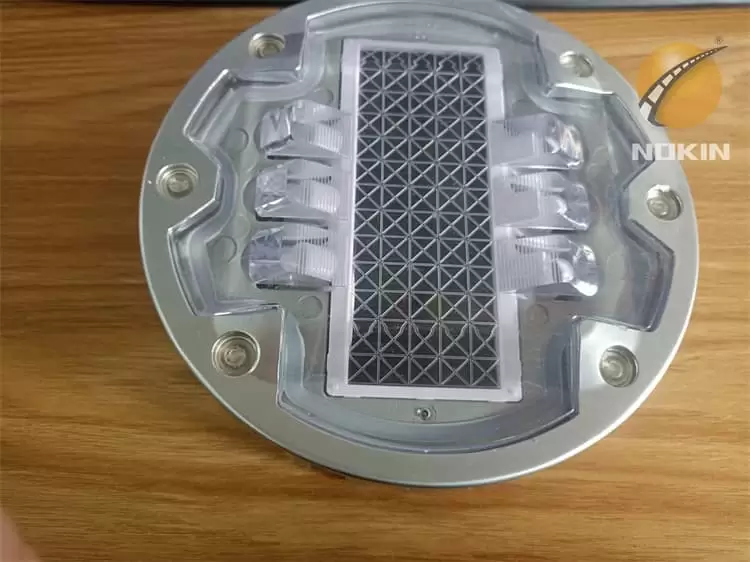

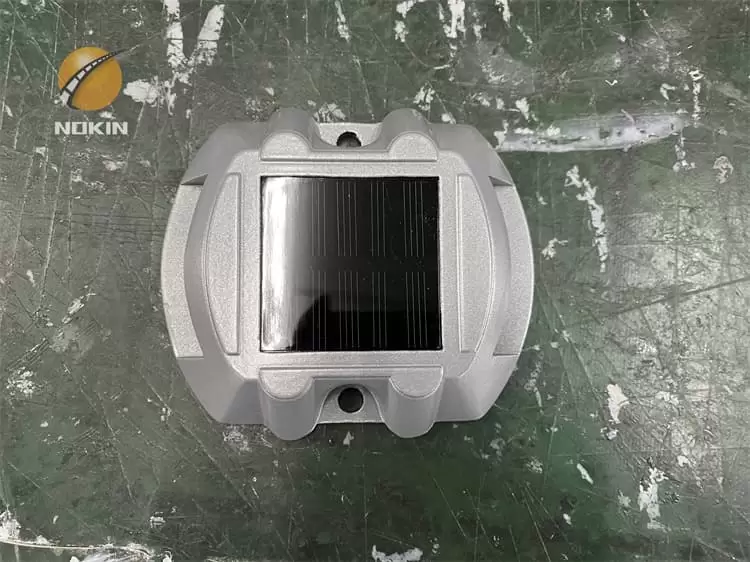

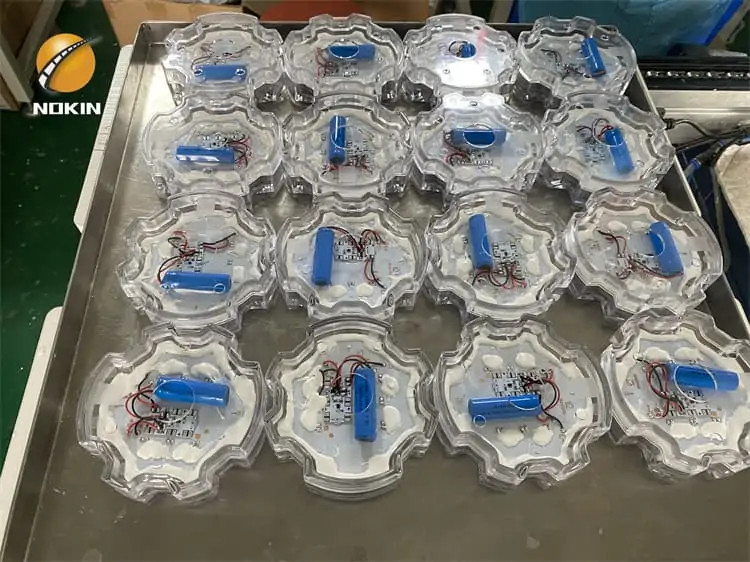

The most important thing for the stability of solar stud light is the core component of solar energy – solar cells. Solar cells are an important factor affecting solar road studs. Therefore, we need to be careful when choosing batteries. There are two types of batteries that meet the standards. You can choose batteries, lithium batteries, and nickel-metal hydride batteries, which determine the life of a battery and can be selected by charging and discharging and battery capacity.

Another point that needs to be considered is that the temperature of the external environment needs to be considered when installing solar stud reflectors. Solar road studs can play their role only in the normal temperature range. If the temperature of the external environment is too high or too low, it will affect the normal operation of the battery. , because there is a certain chemical substance in the battery, only the solar battery can meet the requirements of the actual environment. The requirements of the National Ministry of Transportation are -10 degrees to 50 degrees, but the environment where solar road studs are installed will exceed this range, which requires Putting forward higher requirements for solar cells and external technical support.

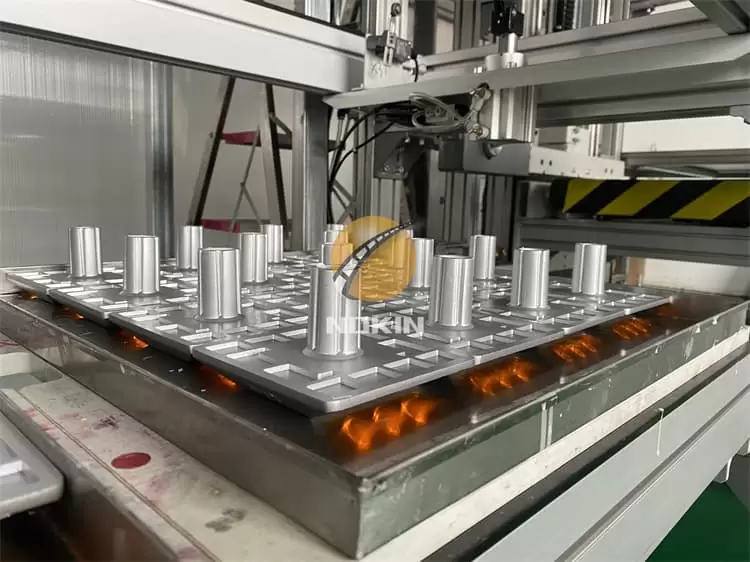

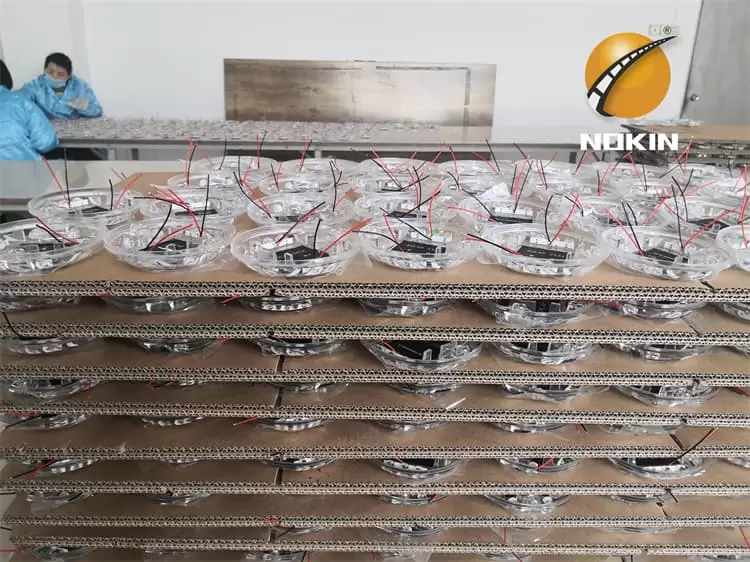

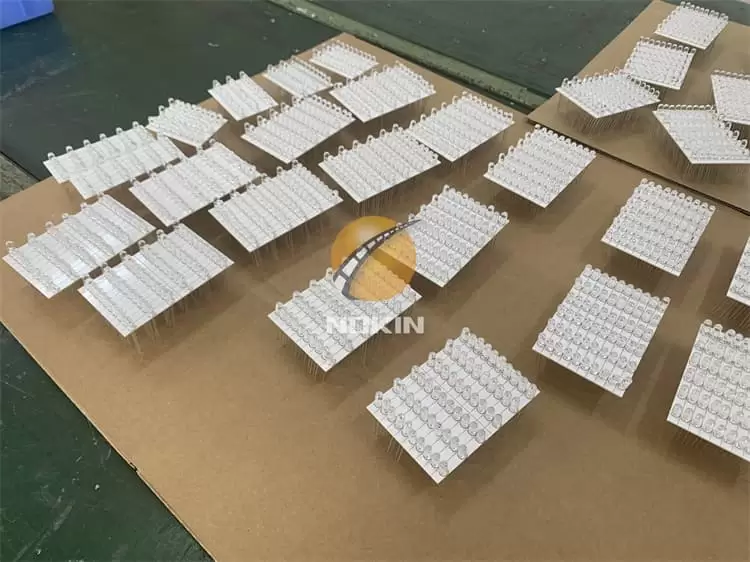

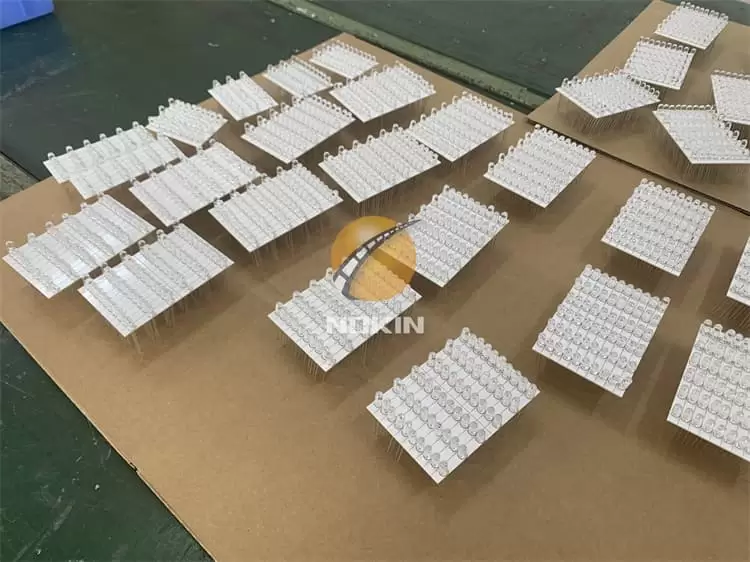

Secondly, the design of the internal electronic circuit of the led solar studs is also very important. This requires designers not to be too complicated when designing solar road studs. If there are too many internal circuits, it will affect the overall design. However, another point is that when producing solar road studs, they must be welded firmly. After the welding is completed, it also needs to be carefully inspected to ensure its quality. Most solar panels use monocrystalline silicon solar panels because of their high photoelectric conversion rate, which can keep solar road studs working normally to a certain extent.

The stability of solar pavement makers needs to be considered from the solar cells, the temperature of the external environment, the design of electronic circuits, firm welding, etc., in order to extend the service life of solar road studs and provide us with a bright future!