Previous:

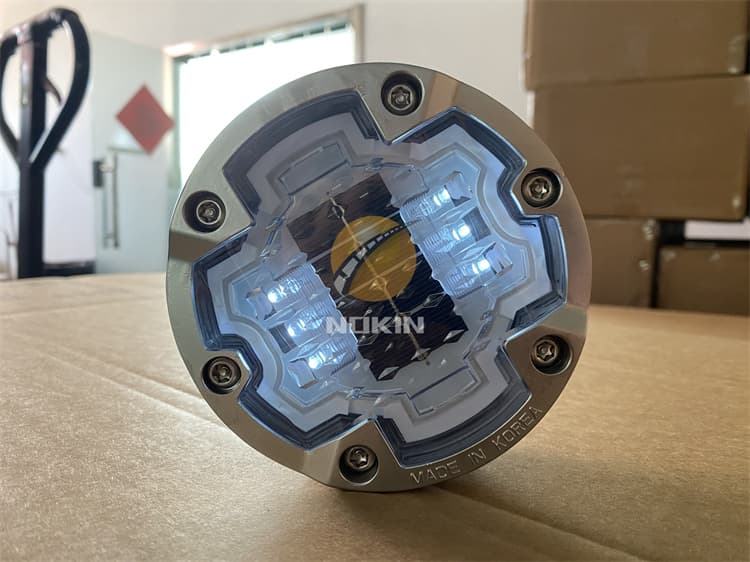

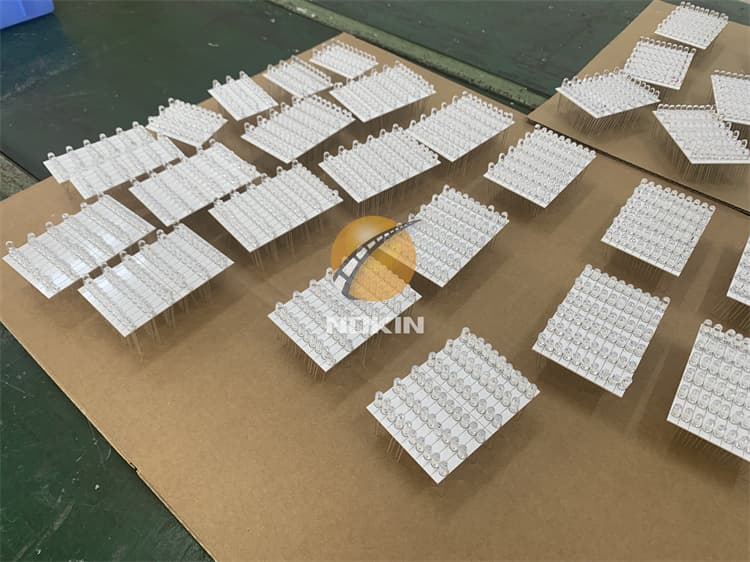

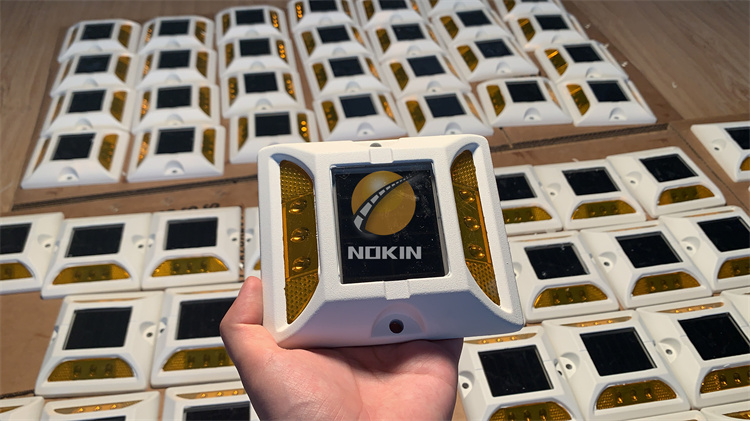

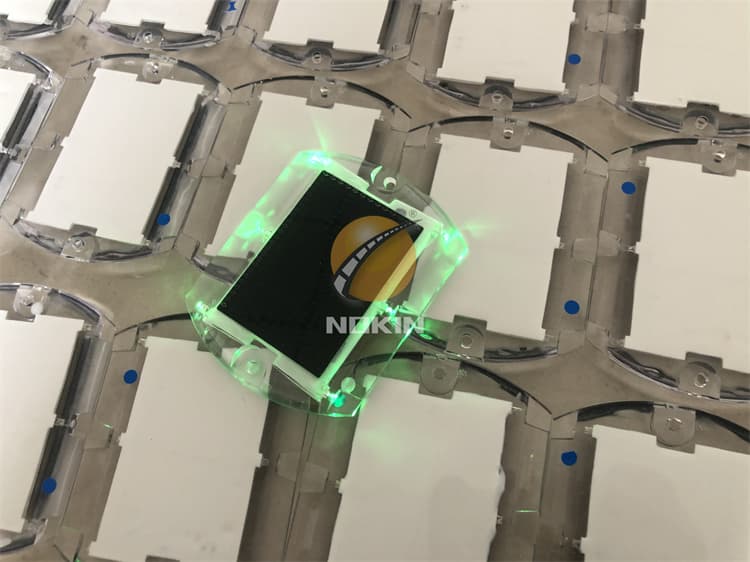

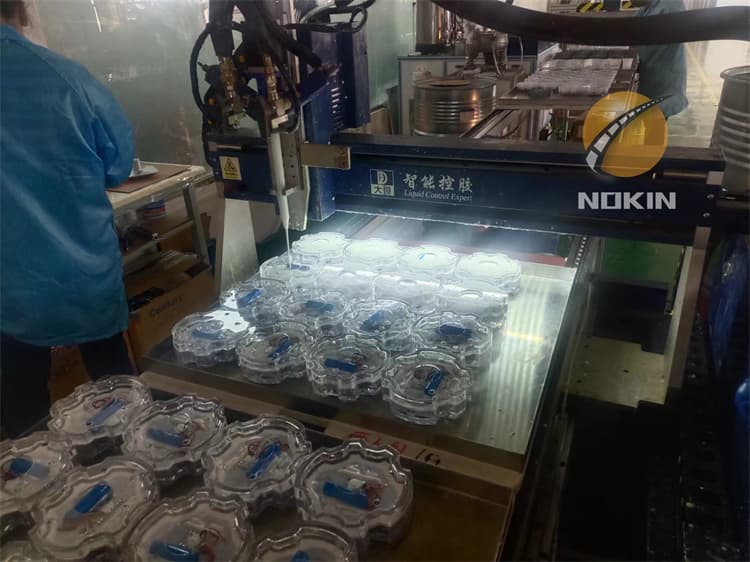

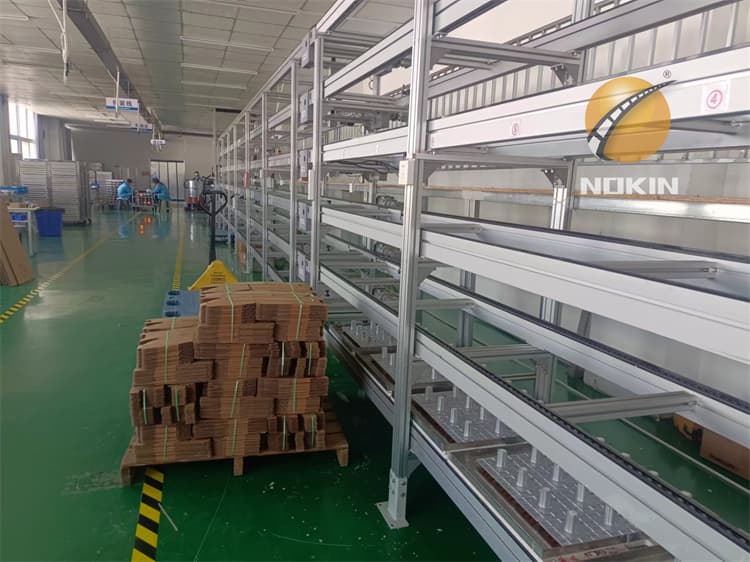

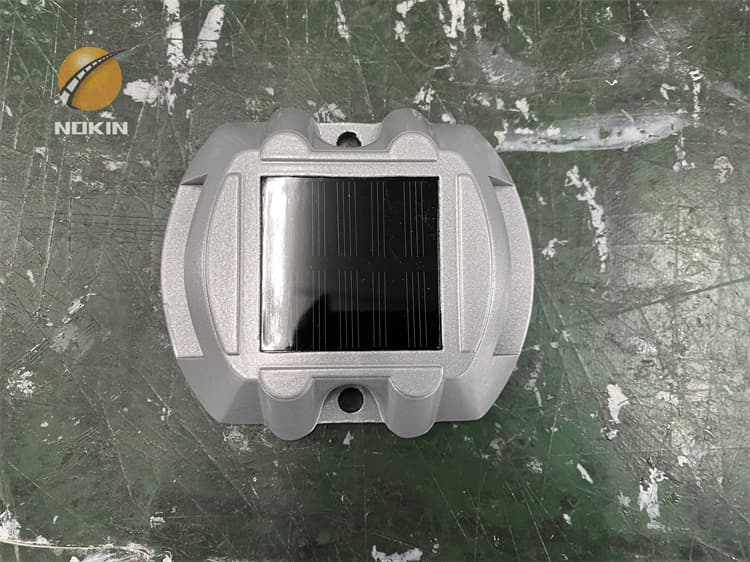

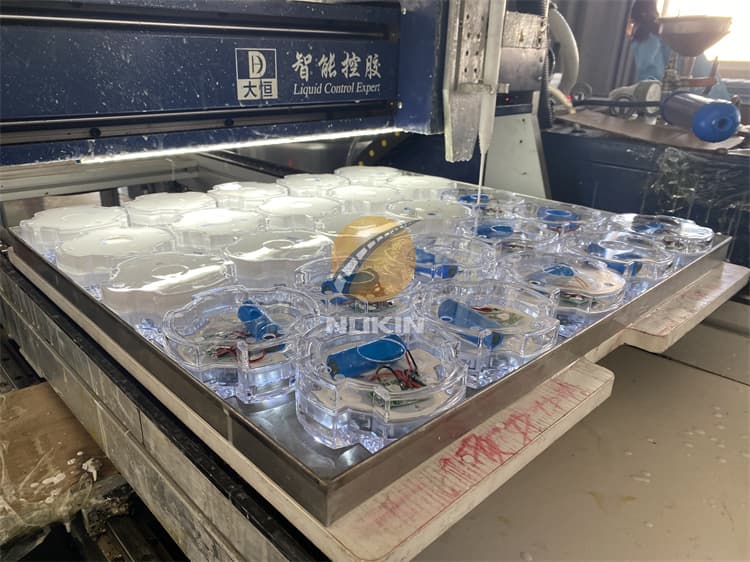

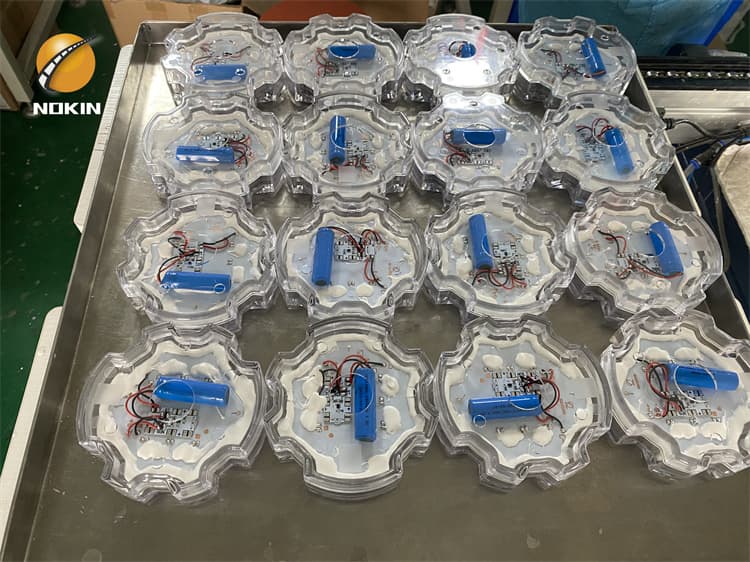

Production of custom solar road studs

Content

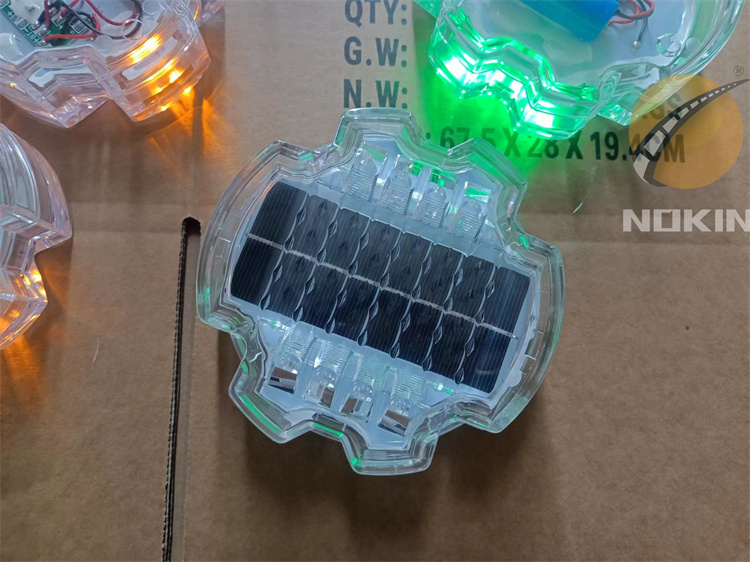

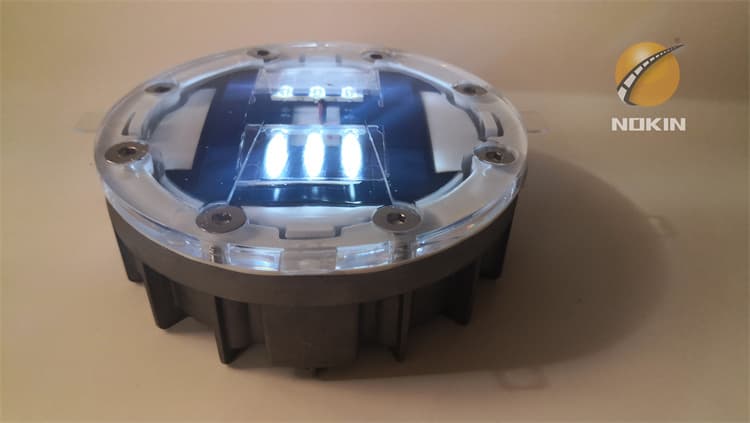

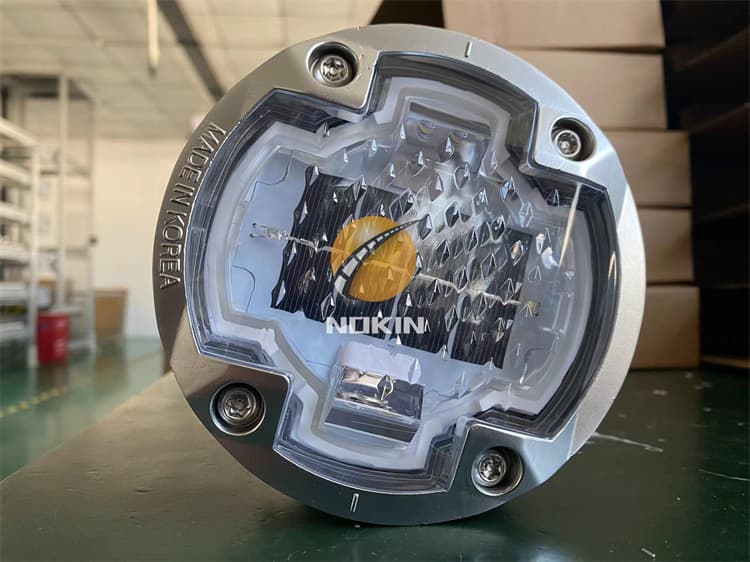

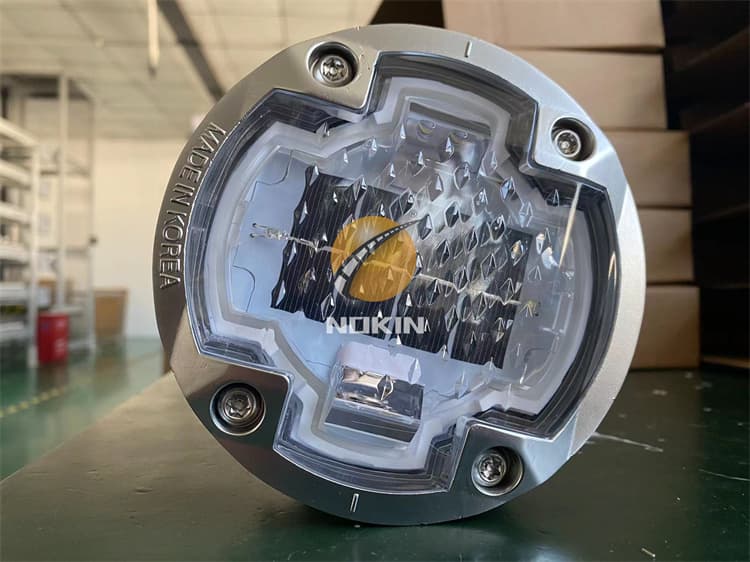

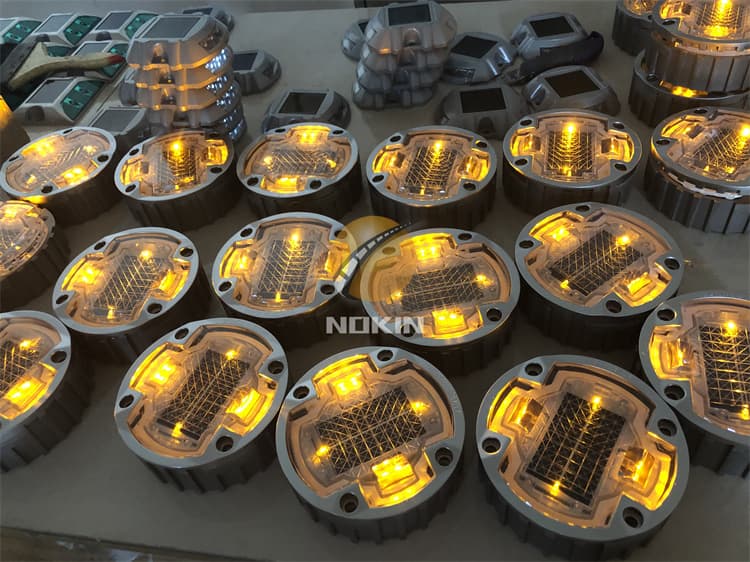

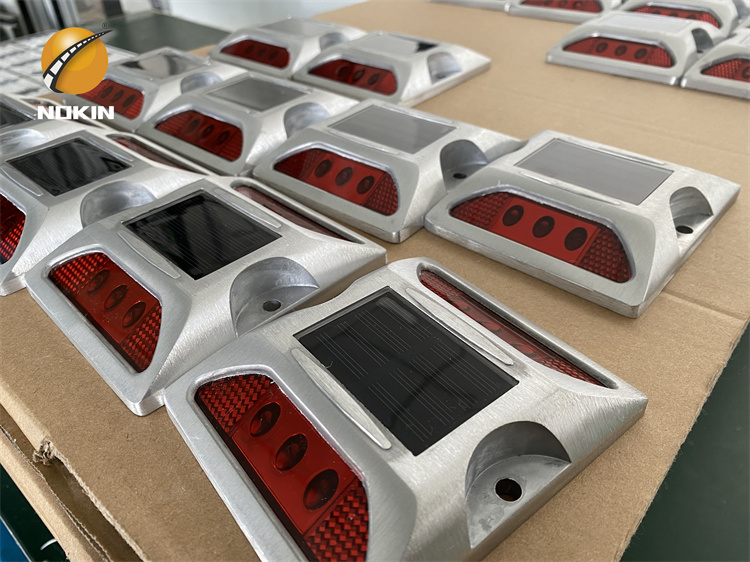

Nokin Solar Road Studs are dusk to dawn LED lights for up to 5 days at a charge. Because Solar Road Studs do not use conventional energy but are powered by solar power, they must be used outdoors (in daylight) to build charges. Solar Road Stud provides flashing warning lights to warn drivers to pay more attention to the upcoming curve, middle, or crosswalk. NOKIN solar road studs are manufactured according to safety standards with high visibility and effectively reduce the risk of traffic accidents. Safety first!

Installation Method Of Raised Solar Road Stud:

Carefully mark the distance between the placement of solar road stud lights. To prevent an adverse effect on the ground, use a proper tool such as Core Drill. Drill 35mm and the depth will be 55mm.

Remove all debris from the installation hole.

Pour epoxy into the holes per the manufacturer’s instruction.

Verify that the installation hole is straight. Verify that the installation hole is large enough to allow the epoxy to surround the solar-led road stud shaft.

Set the lighting surface of the solar road stud to the desired viewing angle. Verify the epoxy is evenly adhering to the installation hole and solar marker shaft. Verify the bottom of the solar road marker is firmly installed on the installation surface allowing for zero surface float; to occur. (space between installation surface and bottom of the solar marker).

After curing the LED solar road stud for 6-8 hours, remove the installation of the isolation facility.

The recommended spacing between each solar road stud is as follows:

Highways and Expressways

7 – 8 yards (5 – 6 meters)

Dangerous Entrances and Exits

4 – 5 yards (2 – 3 meters)

Access or Exit ways for Hospitals, Parking Lots, etc.

0.5 – 3 yards (0.5 – 2 meters)

The spacing between each solar stud is also according to your actual application requirements, the above values are for reference only.

Inquiry

More