solar reflective road marker for truck safety

Solar Road Stud also know as cat eyes,can help to reduce accident at regional rail crossing, intersection and provide guidance and hazard warning to drivers in darkness and bad weathers. The solar system of solar powered marker lights is conducive for reducing environmental impact and saving costs. With more than 15 years of factory experience, led road reflectors produced by our company owns competitive price and offers more choice to global traffic road safety market and trustworthy partners all over the world.

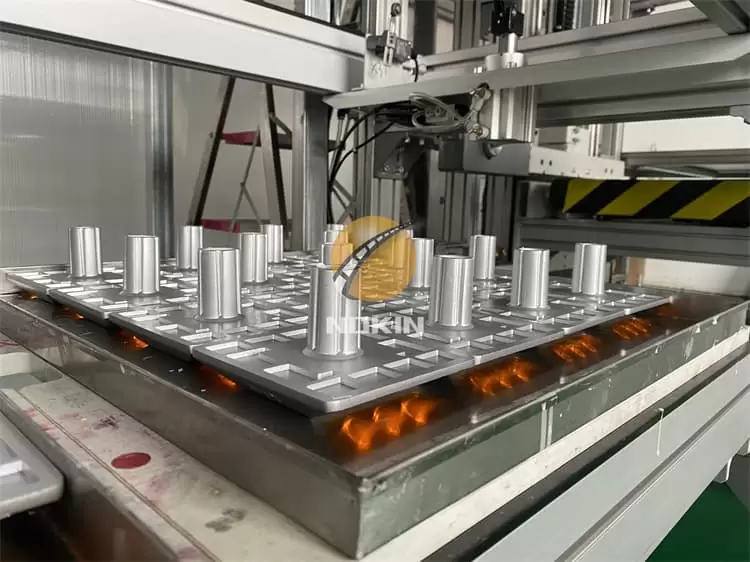

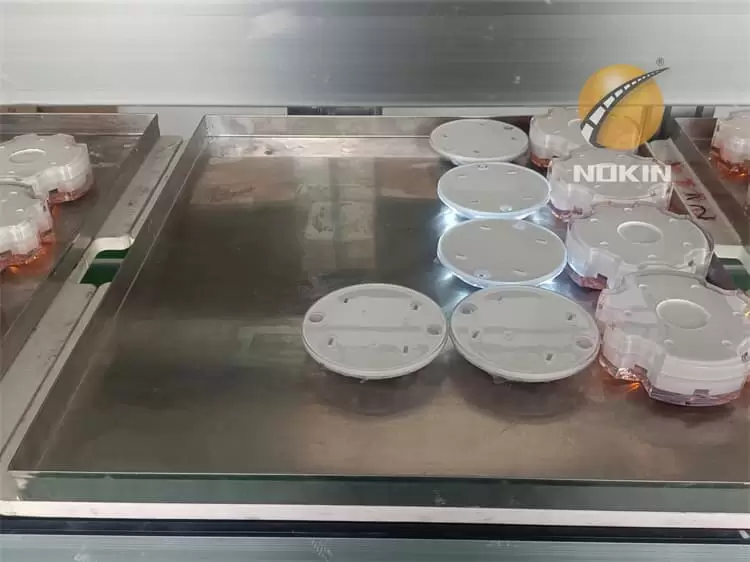

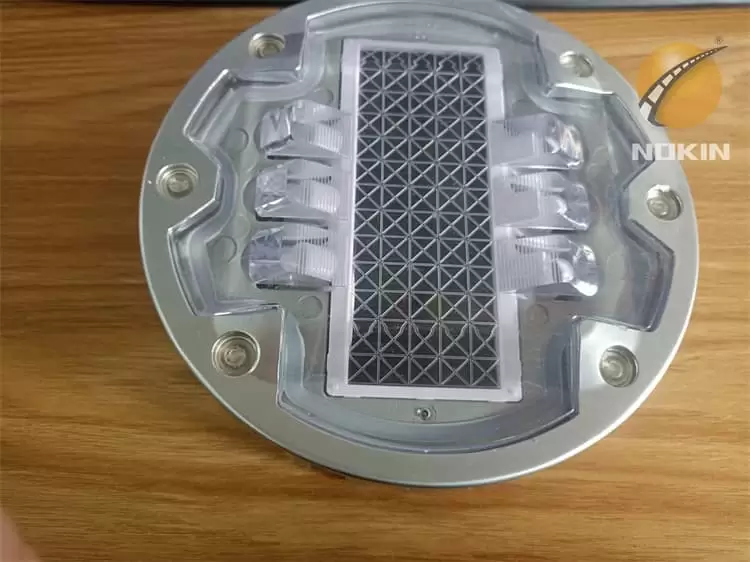

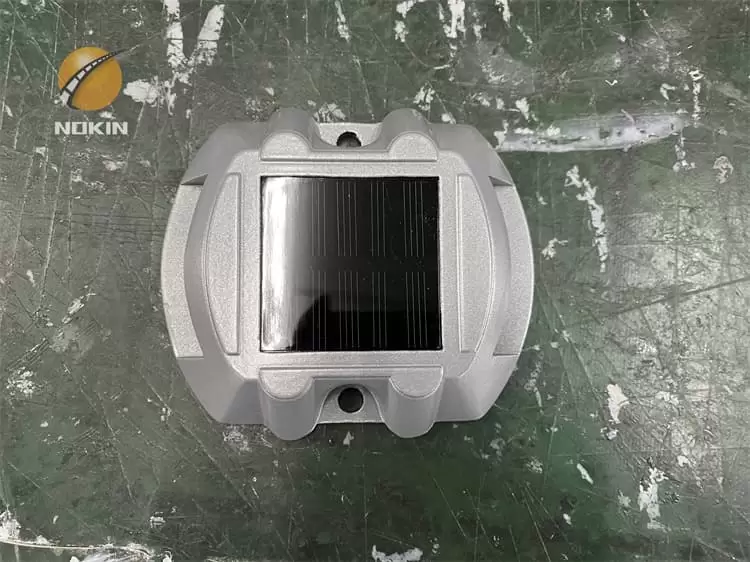

The base of this solar road stud is made of cast aluminum, and the surface is made of plastic spraying technology.

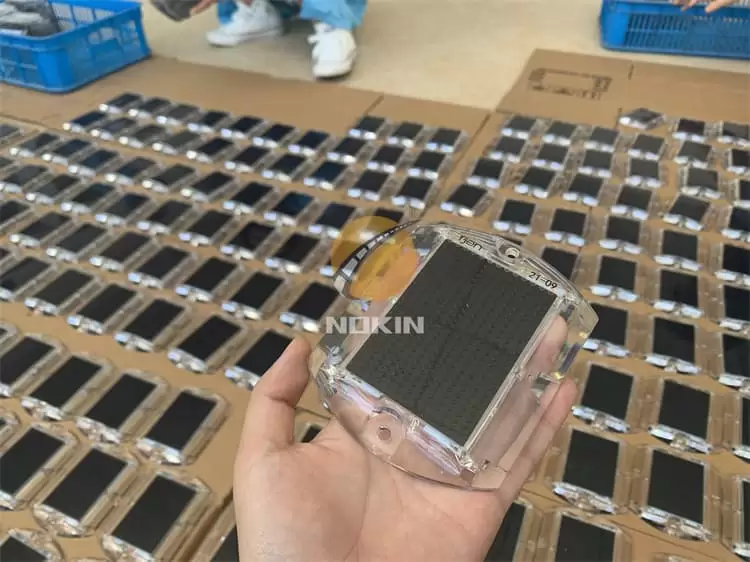

The shell is made of reinforced PC material, which has excellent impact resistance and heat stability

Loading capacity more than 30 tons, can be used in the middle of road.

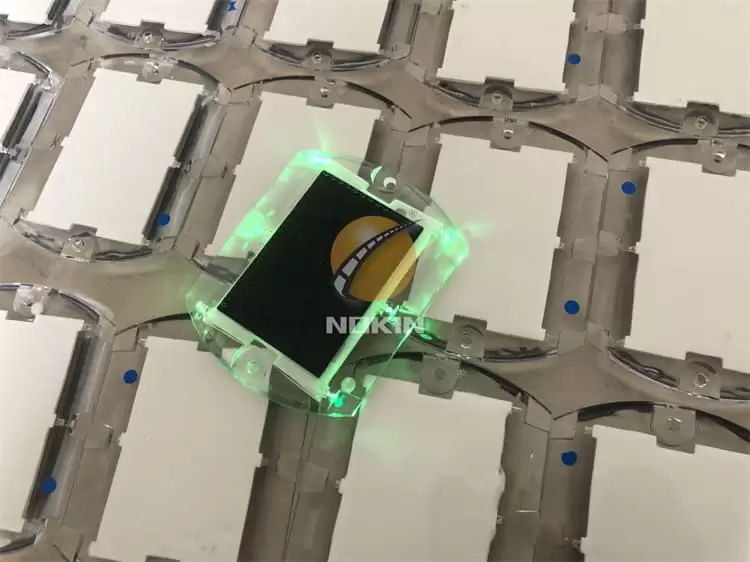

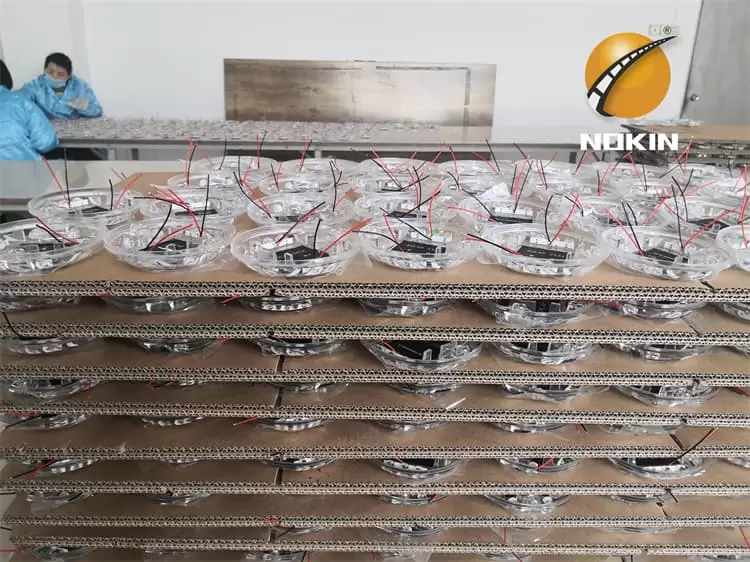

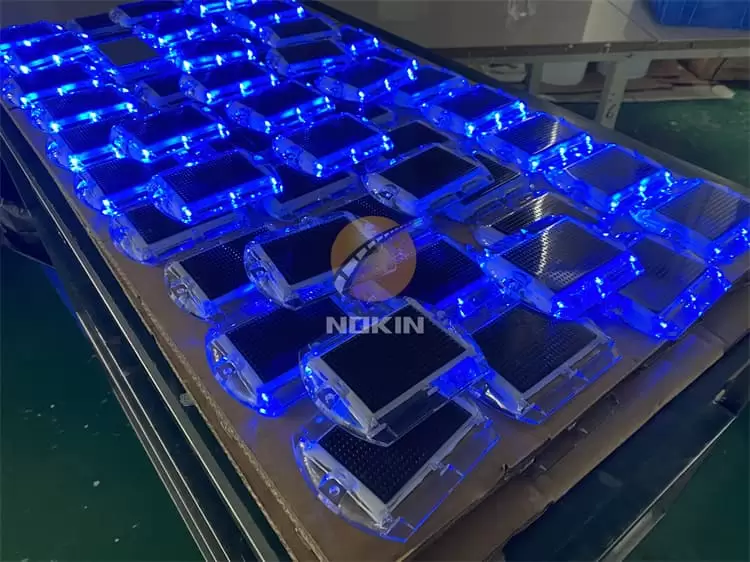

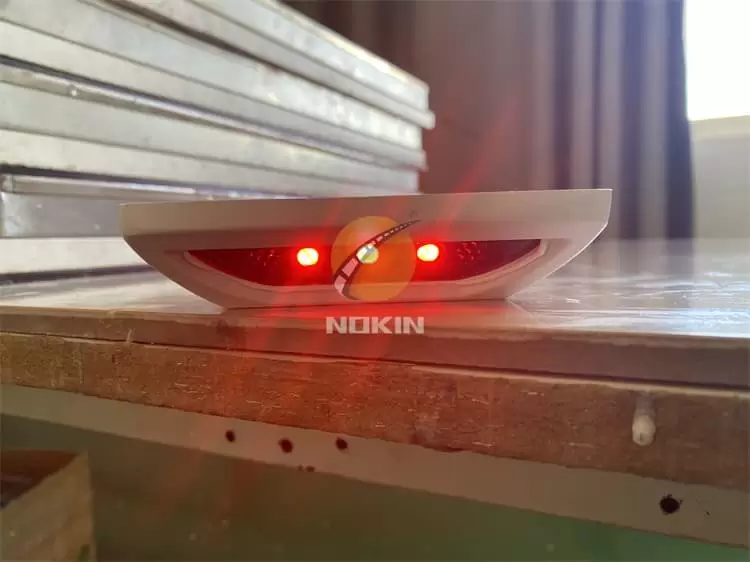

Solar road stud are also named solar raised pavement marker, solar LED road marker and solar cat eye. It is nothing but an “Active Road Stud” with automatic switching function, realized using the combination of a small solar panel, re-chargeable cell, and LED driver circuitry. This type LED road marker clearly visible traffic guidance in all weather conditions. After being energized by the sun, our road stud automatically starts to flash when night falls or with the onset of inclement weather. Solar Road Studs are specifically used to improve safety, reducing accidents on the road by providing information to drivers about the road ahead directly in their natural field of vision

Solar Road Stud also know as cat eyes,can help to reduce accident at regional rail crossing, intersection and provide guidance and hazard warning to drivers in darkness and bad weathers. The solar system of solar powered marker lights is conducive for reducing environmental impact and saving costs. With more than 15 years of factory experience, led road reflectors produced by our company owns competitive price and offers more choice to global traffic road safety market and trustworthy partners all over the world.

The base of this solar road stud is made of cast aluminum, and the surface is made of plastic spraying technology.

The shell is made of reinforced PC material, which has excellent impact resistance and heat stability

Loading capacity more than 30 tons, can be used in the middle of road.

Working Principle of Solar Road Stud Light

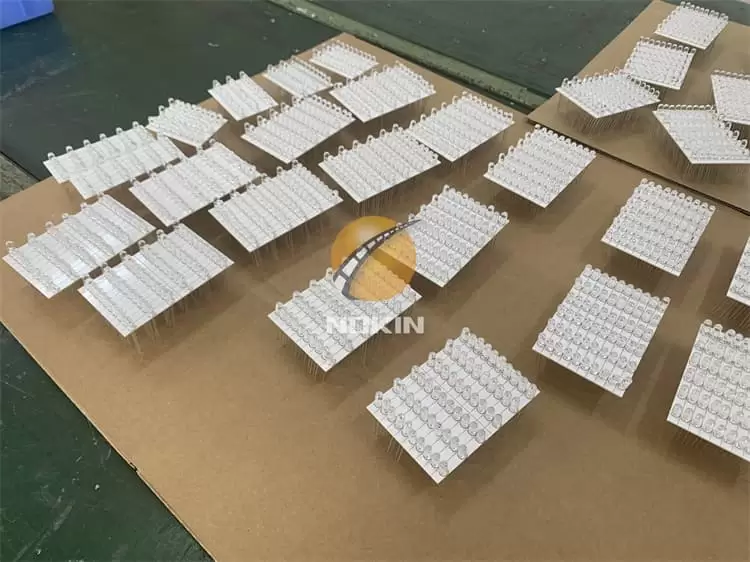

- High brightness America brand led light with 100000 hours of working time.

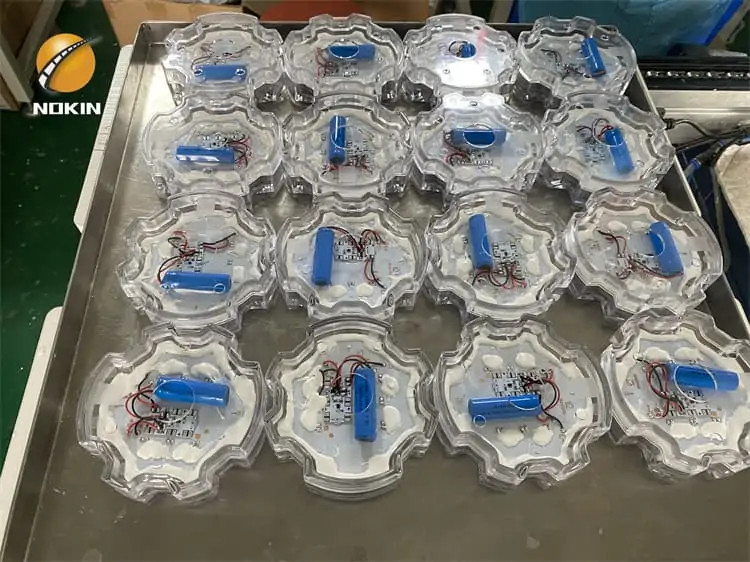

- USA brand solar panel 22% high conversion rate. Fast charge rate.

- Thickness only 10 mm,Ledd road stud friendly to bicycle and motorcycle wheels.

- Anchor holes or adhesive bond for dual fixation.

- Long life span 5-8 years.

- Led solar road stud accept OEM/ODM.

Installation Method Of Raised Solar Road Stud

1. Determine the installation location and distance, clean the road surface, and ensure that the solar road studs are installed on a flat road surface.

2. Clean the bottom of the solar road stud and apply the epoxy glue evenly to the back of the studs.

3. Press the side with the glue on the road, fix the position, wait for the glue to dry.

4. Check within 2 hours of installation to ensure that all studs are not installed incorrectly and are not bent or deformed due to compression.

5. Remove the installation isolation facility within 6-8 hours after the installation of the solar road studs.

The recommended spacing between each solar road studs are as follows:

Highways and Expressways

7 – 8 yards (5 – 6 meters)

Dangerous Entrances and Exits

4 – 5 yards (2 – 3 meters)

Access or Exit ways for Hospitals, Parking Lots, etc.

0.5 – 3 yards (0.5 – 2 meters)

The spacing between of each solar studs also according to your actual application requirements, the above values are for reference only.