solar road stud pathway Anti-UV wired

Classification of the Solar Road Stud

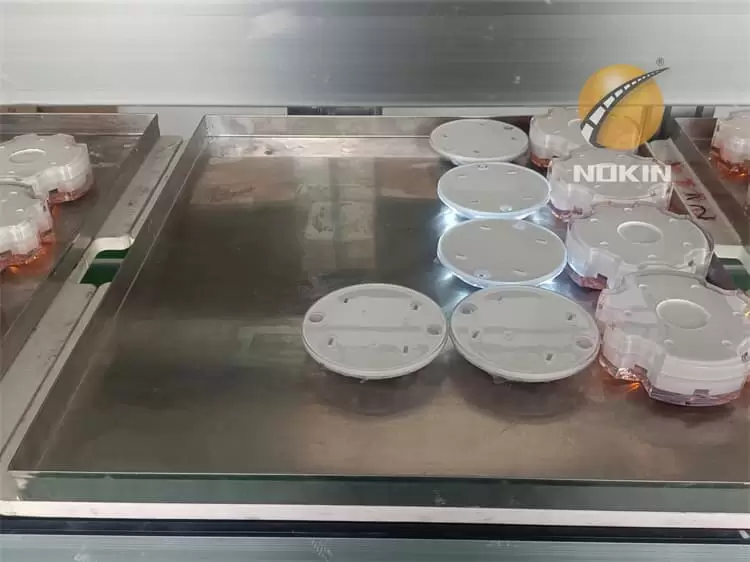

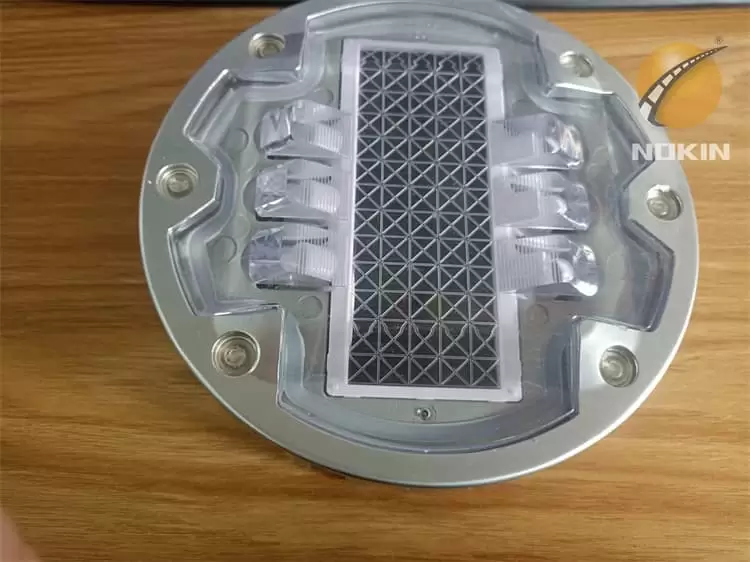

The solar road studs can be divided into embedded type and raised type according to the difference of installation place.

Generally, the former will be used in central lines, and the latter will be used sidelines. That is because the solar road studs that installed in the central lines should have strong pressure resistance, and in order to solve this problem, the workers should have to embed the studs into the roads, and only leave 5 mm on the road surface. And the pressure resistance of the solar road studs installed in the sidelines does not require that high as the studs installed in the central lines, so it can work effectively even the raised type is used.

The solar road studs can also be divided into two types according to the difference of the storage devices, and one uses the capacitance, and the other uses the battery. For these two types, the life span of the former one can be 5 to 7 years, and that of the latter one is 1 to 3 years.

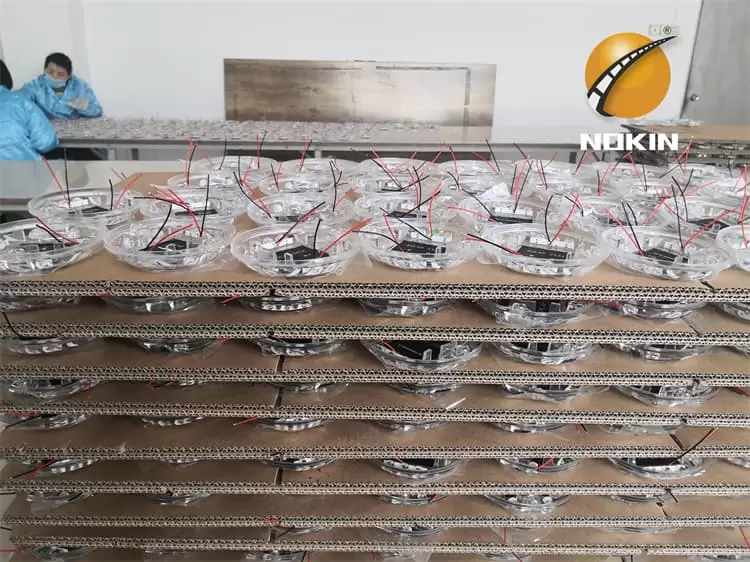

For the embedded solar road studs do more harm to road surface, and the cost of capacitance solar road studs are relatively high, so the raised types are widely used nowadays.

Classification of the Solar Road Stud

The solar road studs can be divided into embedded type and raised type according to the difference of installation place.

Generally, the former will be used in central lines, and the latter will be used sidelines. That is because the solar road studs that installed in the central lines should have strong pressure resistance, and in order to solve this problem, the workers should have to embed the studs into the roads, and only leave 5 mm on the road surface. And the pressure resistance of the solar road studs installed in the sidelines does not require that high as the studs installed in the central lines, so it can work effectively even the raised type is used.

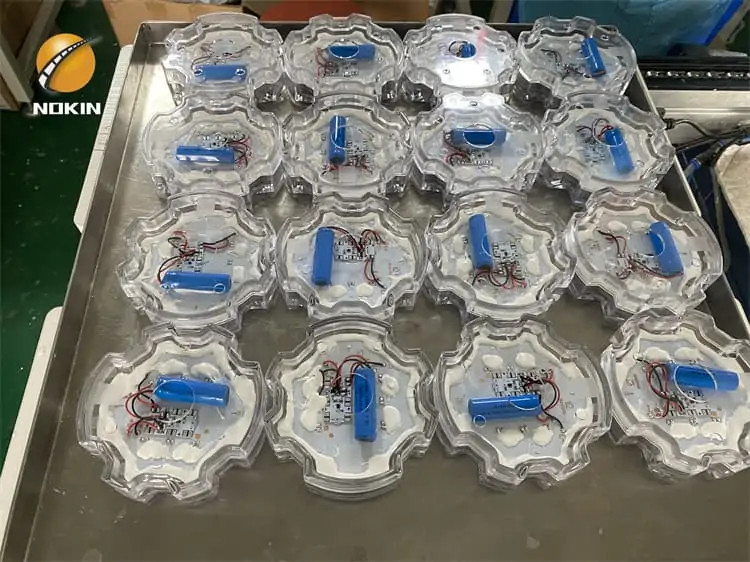

The solar road studs can also be divided into two types according to the difference of the storage devices, and one uses the capacitance, and the other uses the battery. For these two types, the life span of the former one can be 5 to 7 years, and that of the latter one is 1 to 3 years.

For the embedded solar road studs do more harm to road surface, and the cost of capacitance solar road studs are relatively high, so the raised types are widely used nowadays.

Performance Indicators of the Solar Road Stud

When research the basic characteristics of any kind of solar road stud, the following aspects should be considered.

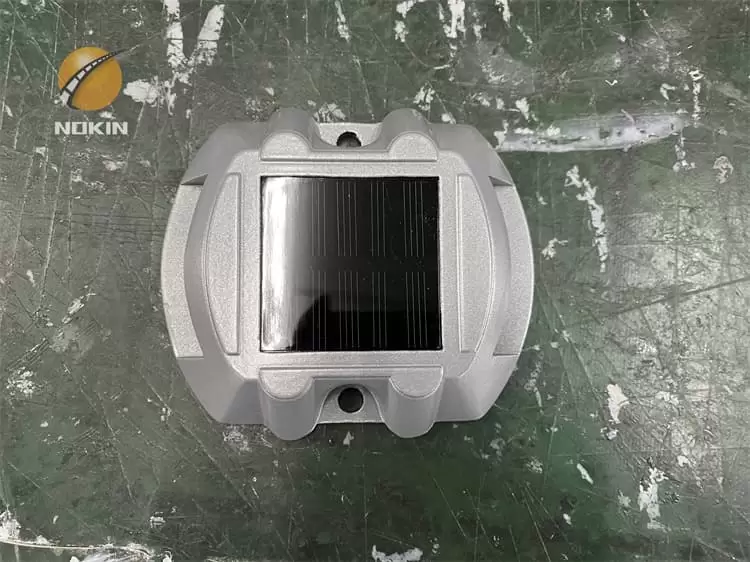

1. Pressure Resistance

If the solar road stud cannot work under a certain extent of pressure, it will be out of work after several times crush or crash. So the compression resistance should be the most basic condition for the solar road stud. For the solar road stud is a electronic product, it is not that easy to make the road stud has strong pressure resistance. Thus the pressure resistance of the solar road stud is lower than the ordinary road stud.

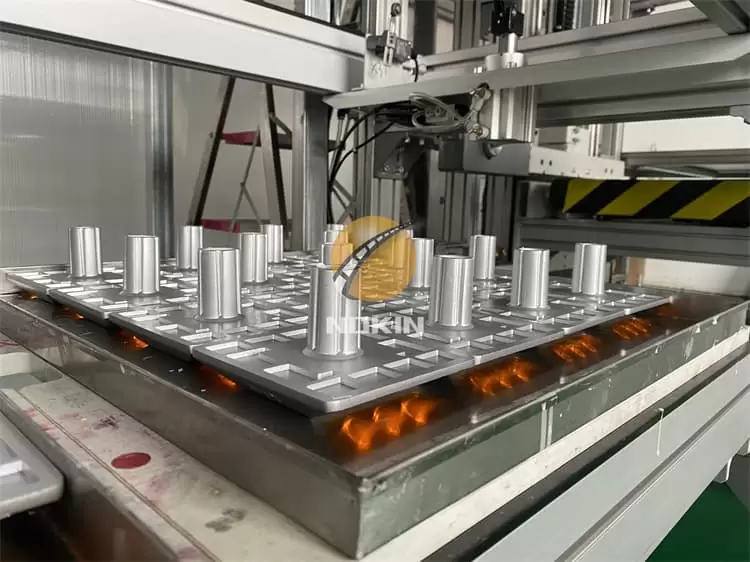

There are several methods to increase the pressure resistance of solar road stud: 1). Use the PC bullet resistant material to make the solar panel outside to increase the pressure resistance of the electronic part of the road stud; 2). Use the IC control to decrease the volume of electronic circuit; 3. Put the reinforcing ribs on the shell to share the pressure on the electronic part.

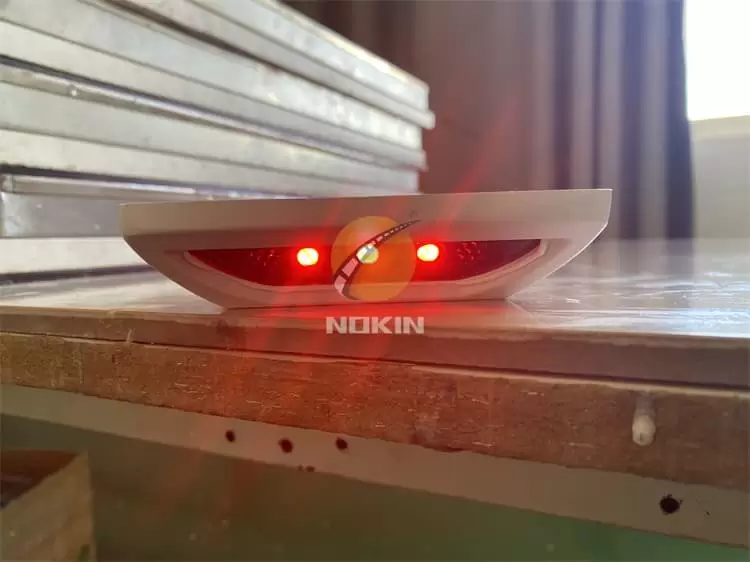

2. Sealing property

The water will permeate into the solar road stud if it is not sealed tightly, which will cause short circuit, so the sealing property of the solar road stud should be good.

Several methods are provided to increase the sealing property of the solar road stud:

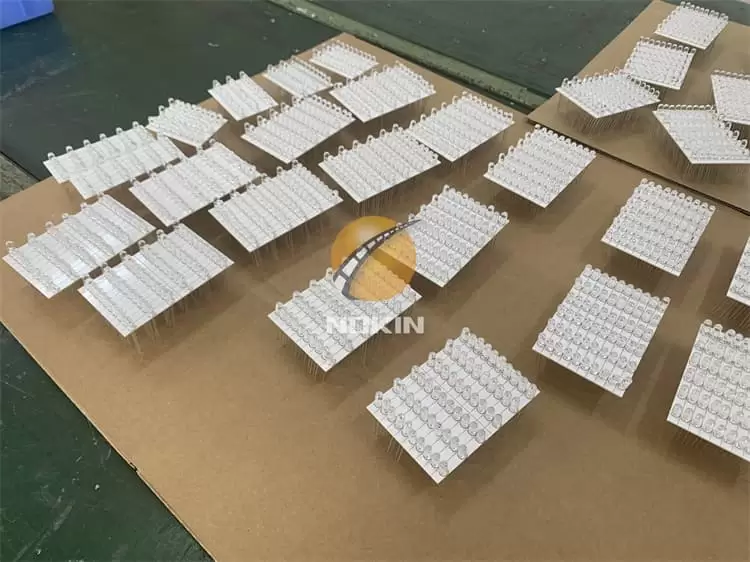

1). Separation design. Adopted separation design of the led lampshade and the circuit board inside the road stud, and even the led lampshade is out of work, there will be no water permeating inside the solar road stud.

2). Using the strong neutral adhesive to ensure that the solar panel, led lampshade and the shell of road stud can bond tightly, and there is no gap between them.

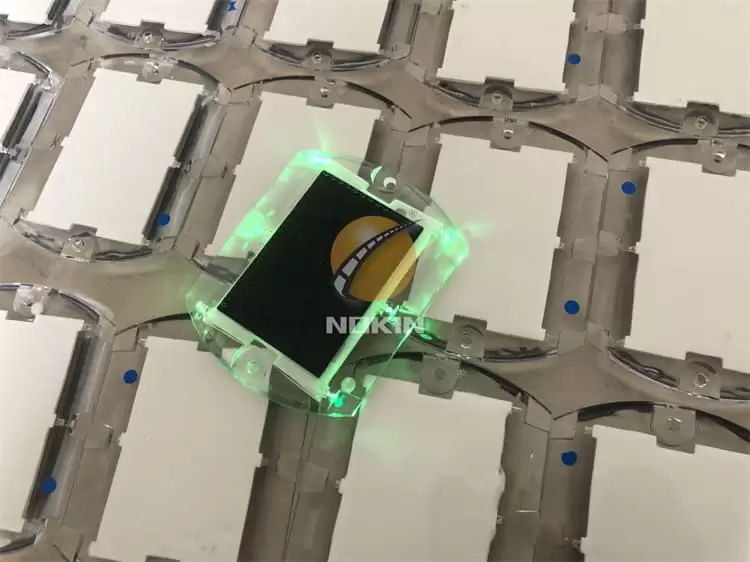

3. Brightness

Solar road stud has one special characteristic when compared with common road stud, and that is, it must auto luminescence. The transportation sector has relative standard for this index, which is 2,000MCD.