solar road stud roadside PC gps

Installation Method Of The Road Stud

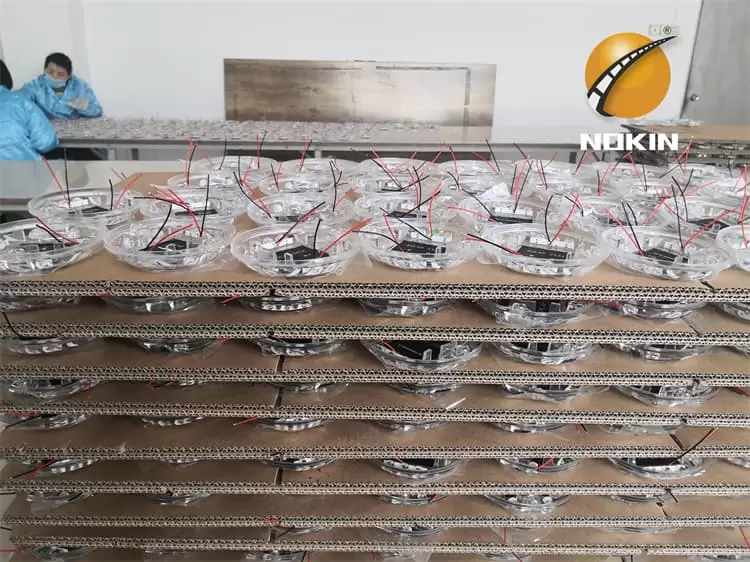

Separation facilities play key role in the installation process. No matter in any conditions, all the workers should be inside the separation facilities. In the road studs are installed in the service roads, the quantity of security officers should be equal to that of the installation workers; if they are installed in un-service roads, the quantity of the installation workers should be three times of that of the security officers.

Make sure that the installation site is even, and if there is an expansion joint or uneven place on the road surface, we should level the ground first.

Use the brush to clean the installation site, and make sure that the places is dry enough.

Smash enough glue on the road stud.

Installation Method Of The Road Stud

- Separation facilities play key role in the installation process. No matter in any conditions, all the workers should be inside the separation facilities. In the road studs are installed in the service roads, the quantity of security officers should be equal to that of the installation workers; if they are installed in un-service roads, the quantity of the installation workers should be three times of that of the security officers.

- Make sure that the installation site is even, and if there is an expansion joint or uneven place on the road surface, we should level the ground first.

- Use the brush to clean the installation site, and make sure that the places is dry enough.

- Smash enough glue on the road stud.

- Press the road stud tightly in the installation site, and make sure that the direction is right. If there is too much glue, we should it up.

- When installing the cast aluminium road stud with foot, make sure that the hold is 1cm deeper than the foot, and the diameter of hole is 2mm longer that that of the foot.

- Make an inspection of the road stud after 2 hours of the installation to make sure that the stud is installed properly.

- Remove the separation facilities 4 hours after solidification.

It is not complex to install the road studs, but there are some details, which play key role to guarantee the quality and service time of the road stud, should be noticed.

Common Problems Of The Road Stud

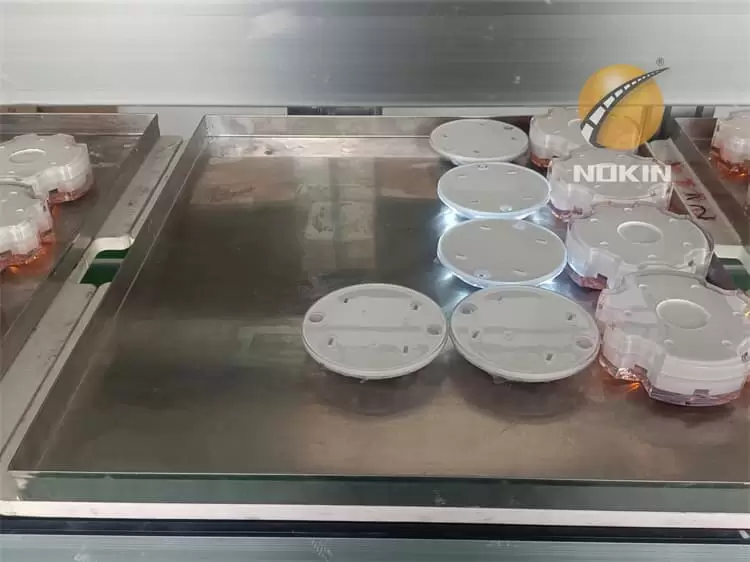

Low Shock Resistance of the Reflector

The key problem of the raised pavement markers sold in the market has low shock resistance, and more than 80% products have this problem. Most of the reflectors are welded into the body of the road stud by ultrasonic, and the reflectors will fall apart with the road stud body when shocked. If the road stud is emerged in rain, the reflector on it will be fade.

Testing method: do shock test on the road stud reflector, and draw out the white panel, then throw down a steel ball weighing 1kg vertical to the surface of the reflector, and emerge it into water, and then test the brightness of the reflector. If there is not water penetration, the brightness won’t decrease.

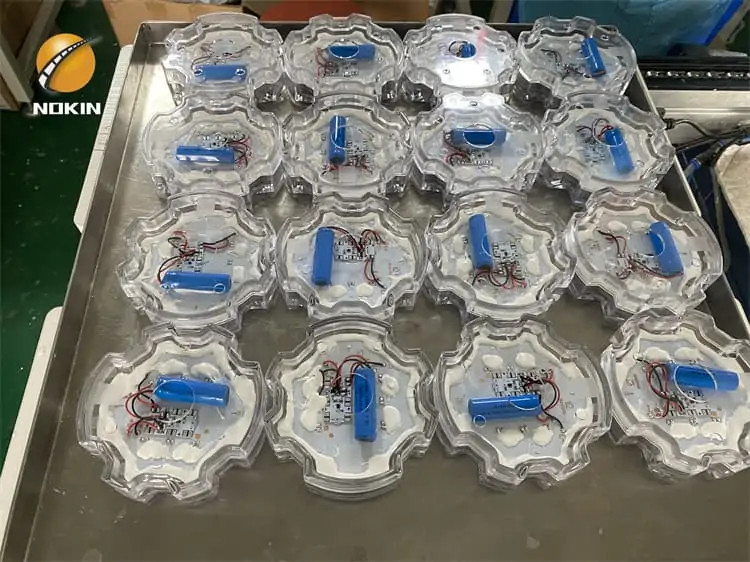

| Product Name | solar road marker light |

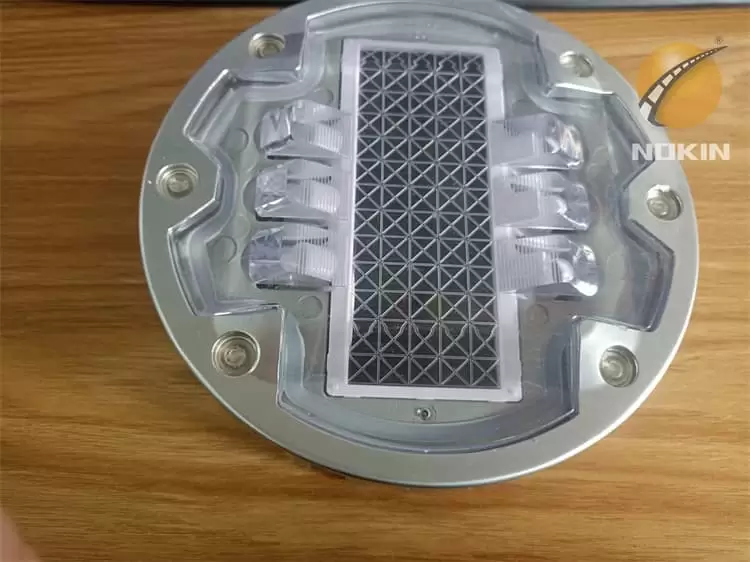

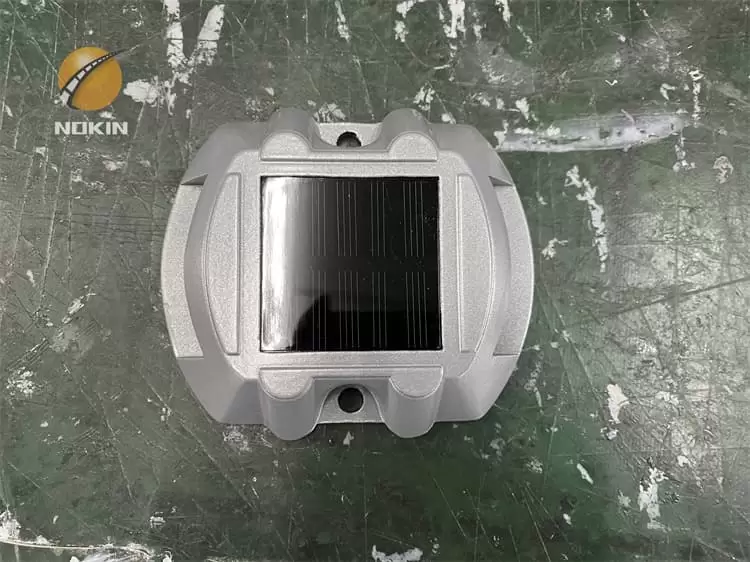

| Body material | Aluminum(GB-ADC12)+PC(Japan Brand) |

| Power supply | USA Brand High Efficient Solar Panel

2.5/150MA for NI-MH battery 5V/60MA for Lithum battery 3v/120MA for super capacitor |

| Battery | NI-MH1.2V/600MAH(high temperature resistance, made in China)

Lithum battery3.2V/500MAH(made in Japan) Super capacitor2.3V/120F(made in Korea) |

| LED | Ultra bright diameter 5mm(4pcs or 6pcs) |

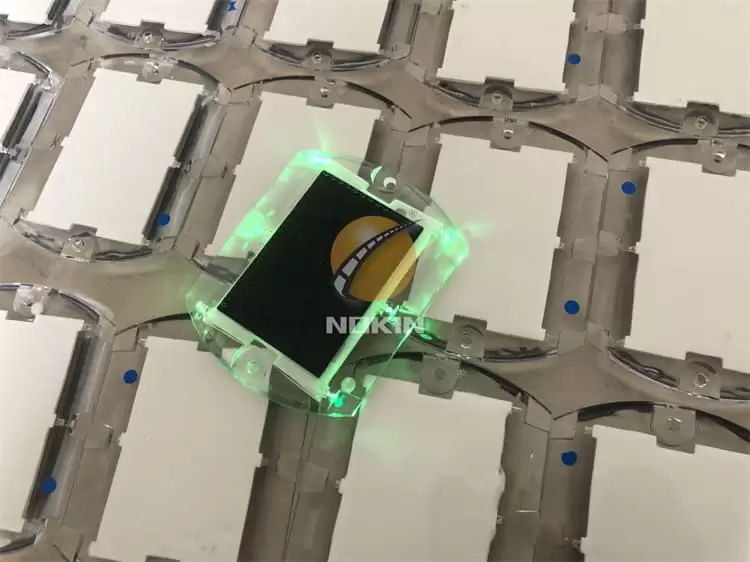

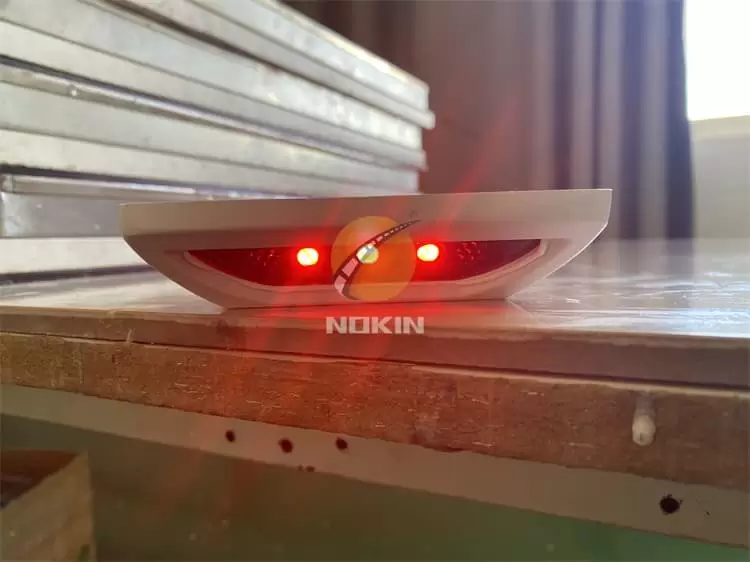

| LED color | Red,Yellow,Green,Blue,White |

| working mode | Recharging at day and working automatically at night |

| Flashing mode | Blinking or constant(flashing frequency 2Hz, also can be made according to your requirements) |

| Working hours | Blinking:140h for NI-MH battery;130h for Lithum battery;

30h for super capacitor after fully charged. Constant: 40h for NI-MH battery;35h for Lithum battery; 15h for super capacitor after fully charged. |

| Water proof | IP68 |

| Visual distance | >800m |

| Life span | 2years for NI-MH battery;

5years for Lithum battery; 10years for super capacitor |

| Load capacity | >30T(can be installed in the middle of road) |

| Size | L125mm*W107mm*H26+50mm |

| Working temperature | -40~85 °C |

| Weight | 1650g/pc |