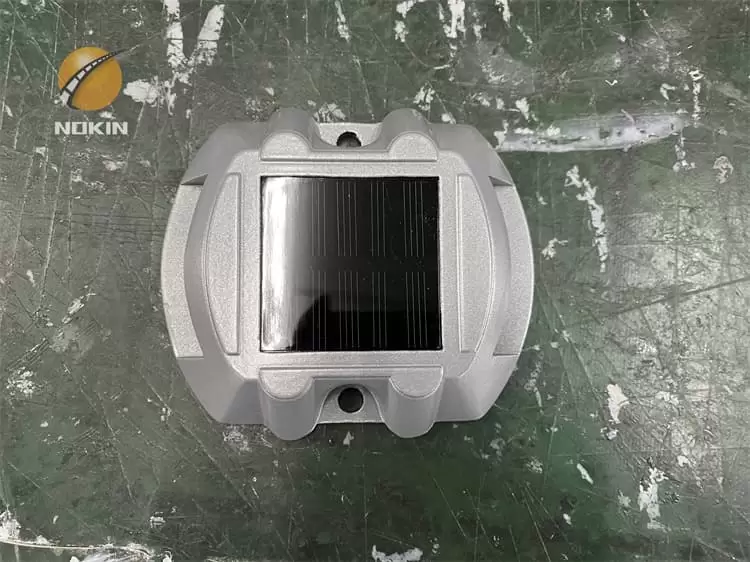

Strong Pressure Solar Road Stud Yellow Color LED

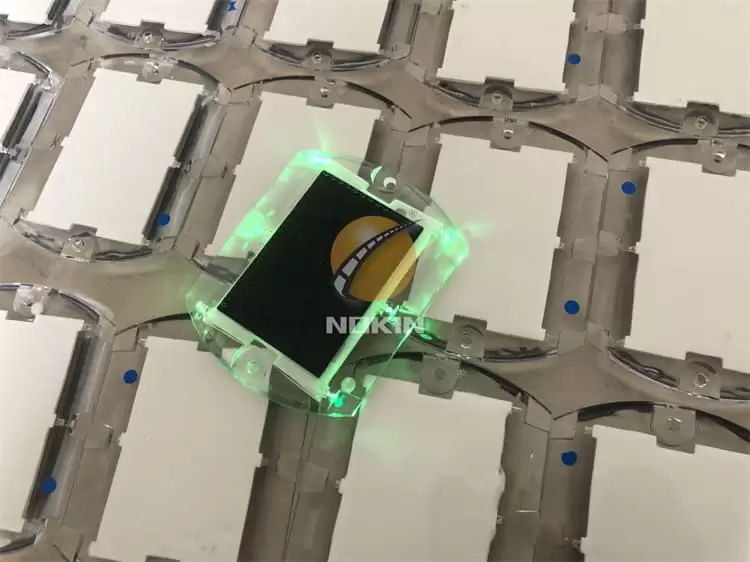

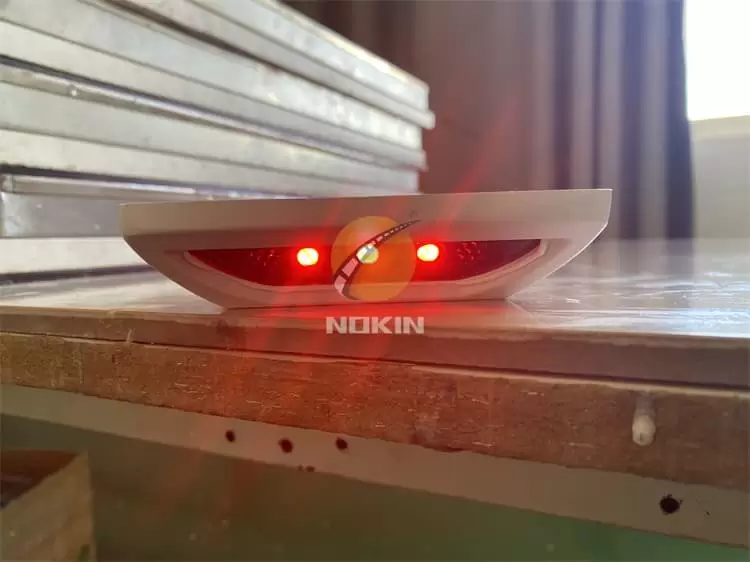

By injecting adhesive or glue internally, the LED solar road stud becomes more resistant to external forces, such as vehicular impact and environmental stress. It helps maintain the integrity and functionality of the solar-powered road studs, ensuring reliable performance and enhanced road visibility for drivers.

Send Inquiry

Quote Online

Share:

Content

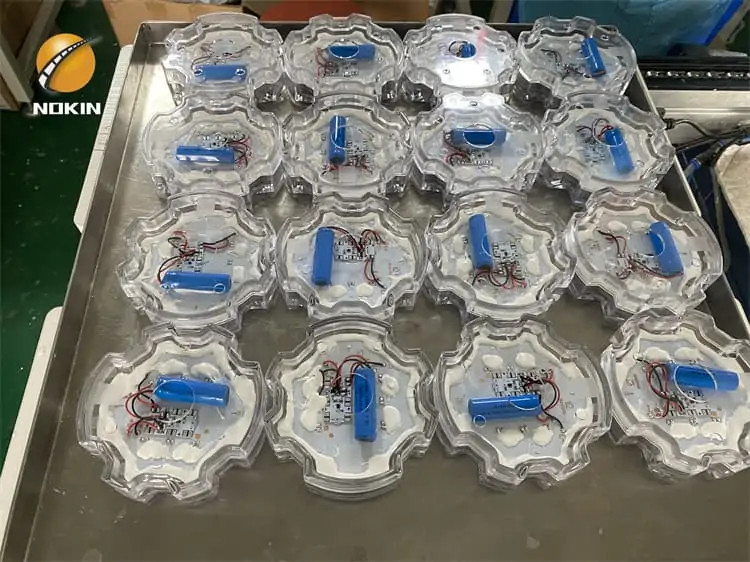

The internal glue injection in solar road studs serves two main functions:

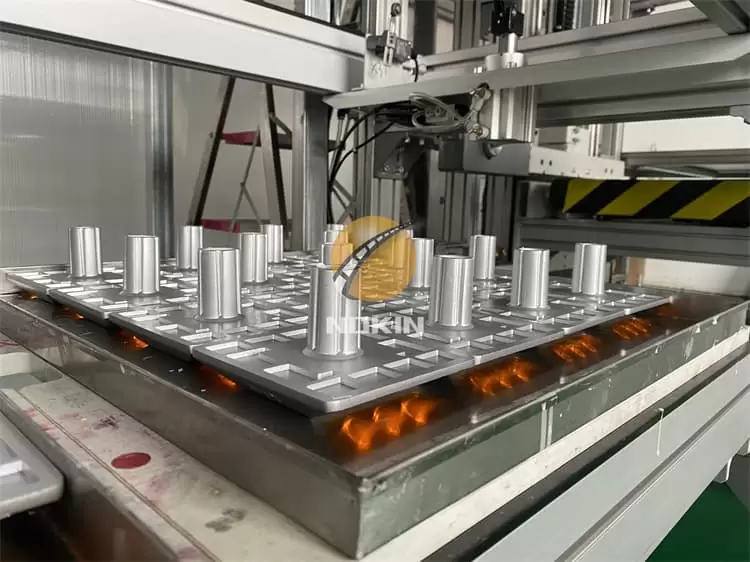

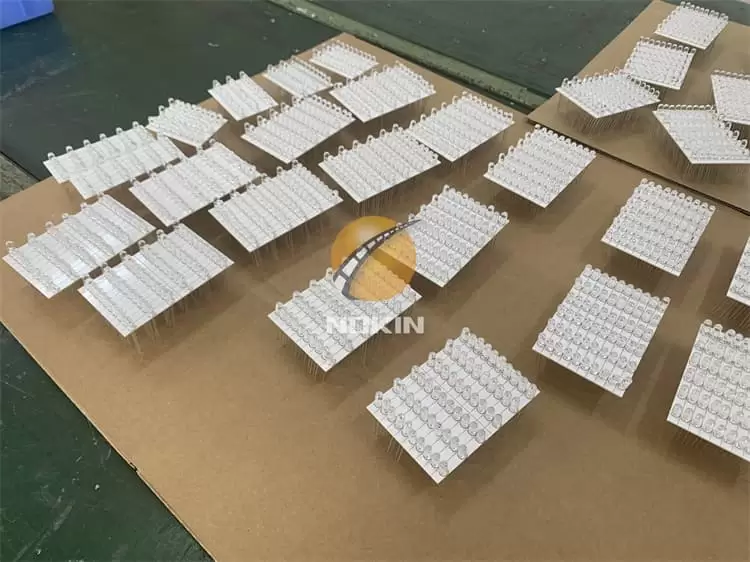

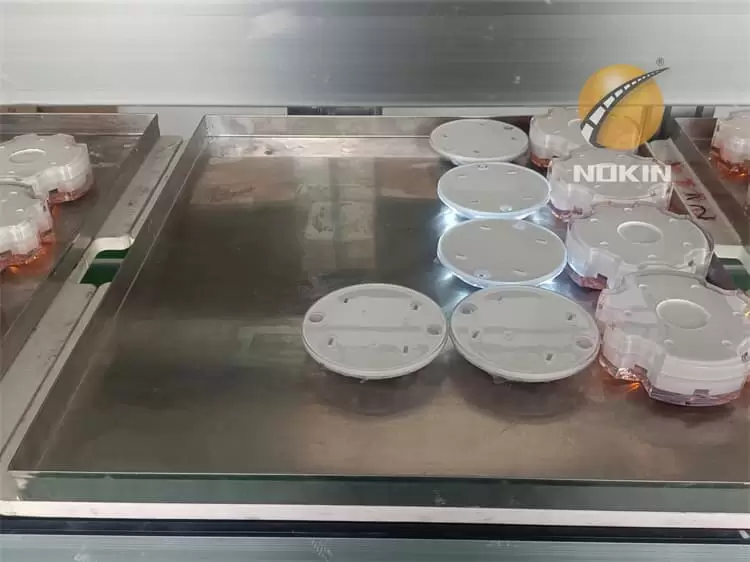

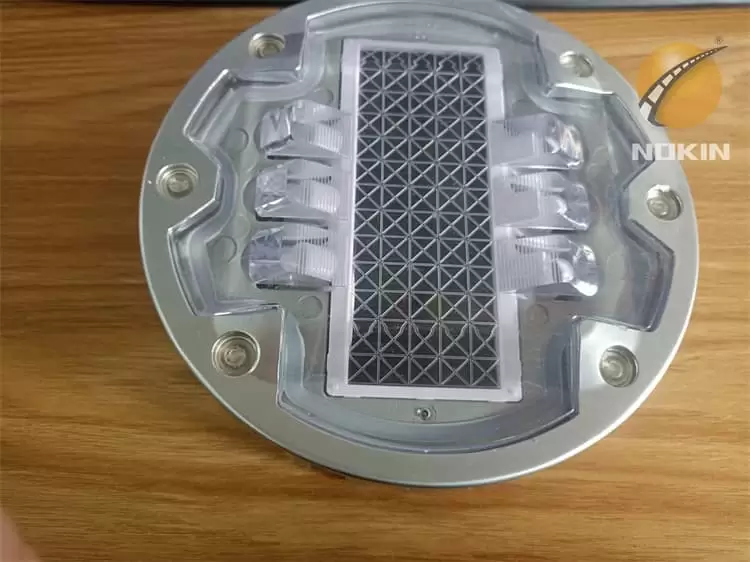

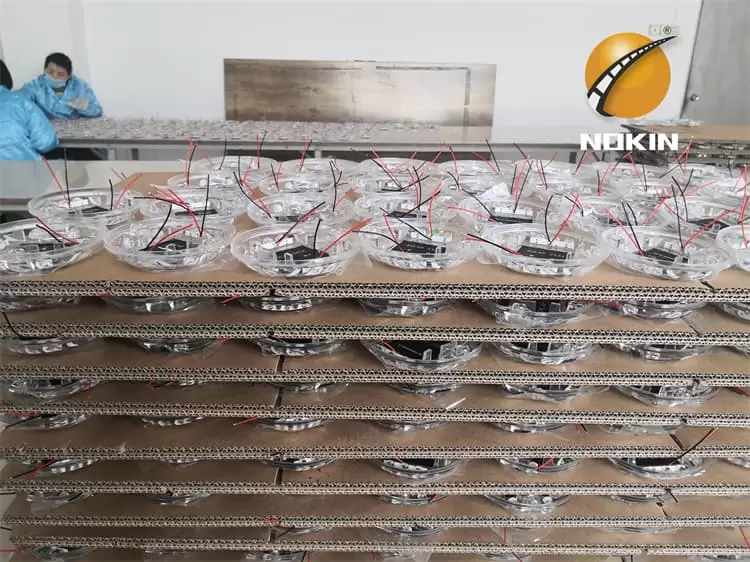

Structural Integrity: Solar road studs are typically installed in the pavement or road surface, and they need to withstand heavy traffic, vibrations, and environmental factors. The internal glue injection helps in securing the components of the solar road stud, such as the solar panel, LED lights, and electronics, firmly in place. It provides structural support and prevents any movement or dislodgment of these components, ensuring the longevity and durability of the stud.

Sealing and Waterproofing: Solar road stud lights are exposed to various weather conditions, including rain, snow, and moisture. The internal glue injection acts as a sealant, preventing water or moisture from penetrating inside the stud and damaging its electronic components. It creates a watertight barrier that protects the sensitive internal circuitry from corrosion, ensuring the proper functioning of the solar road stud over an extended period.

By injecting adhesive or glue internally, the LED solar road stud becomes more resistant to external forces, such as vehicular impact and environmental stress. It helps maintain the integrity and functionality of the solar-powered road studs, ensuring reliable performance and enhanced road visibility for drivers.

Inquiry

More