The Crucial Role of Glue Injection in Solar Road Stud Lights

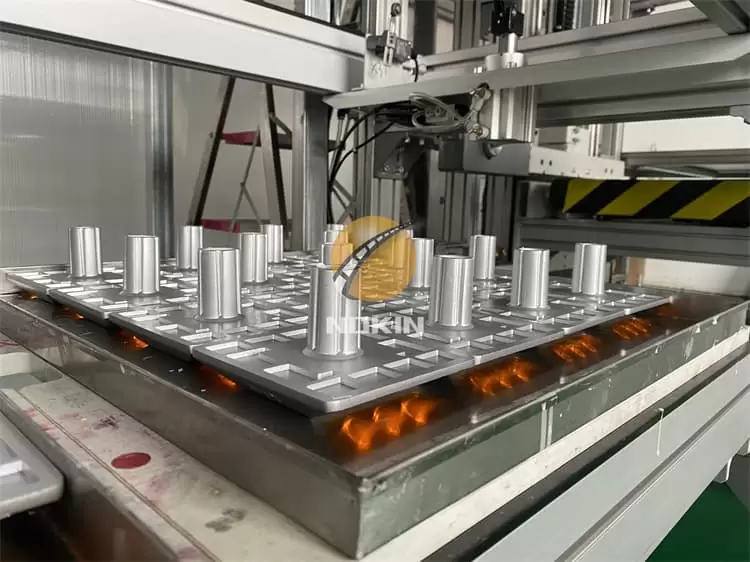

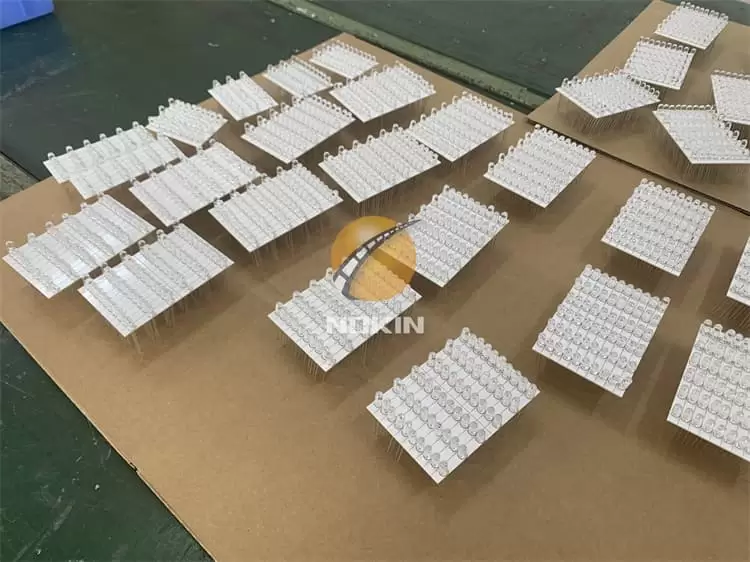

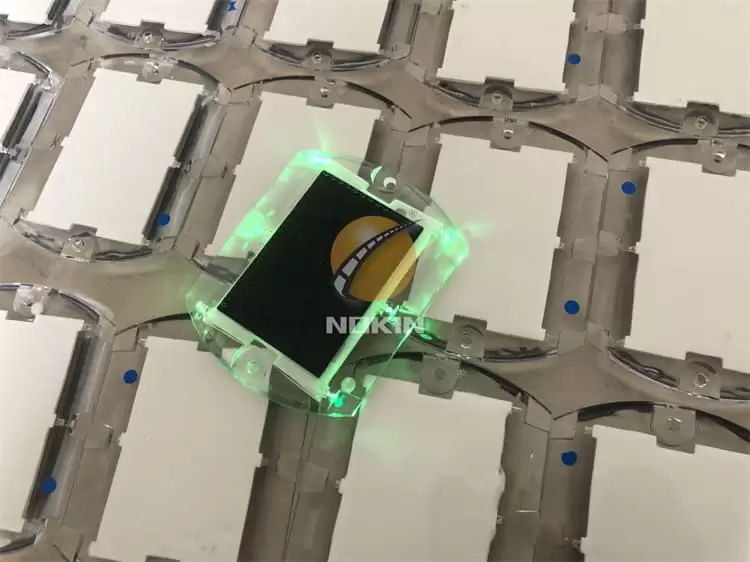

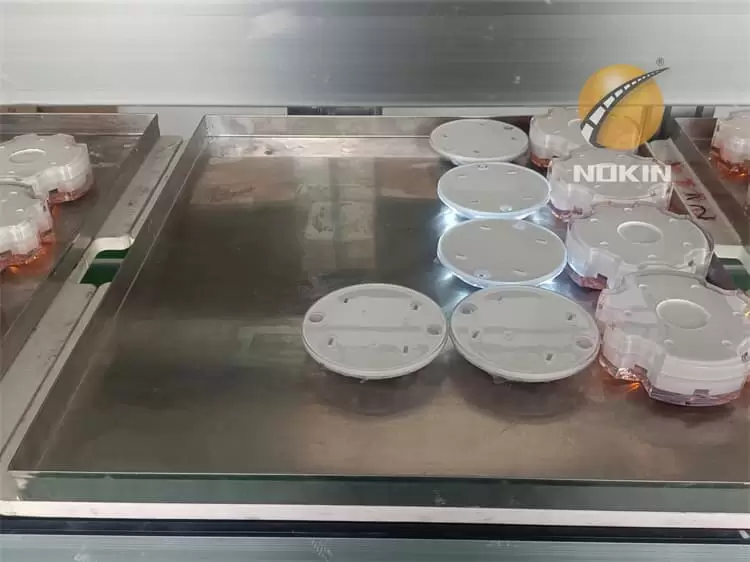

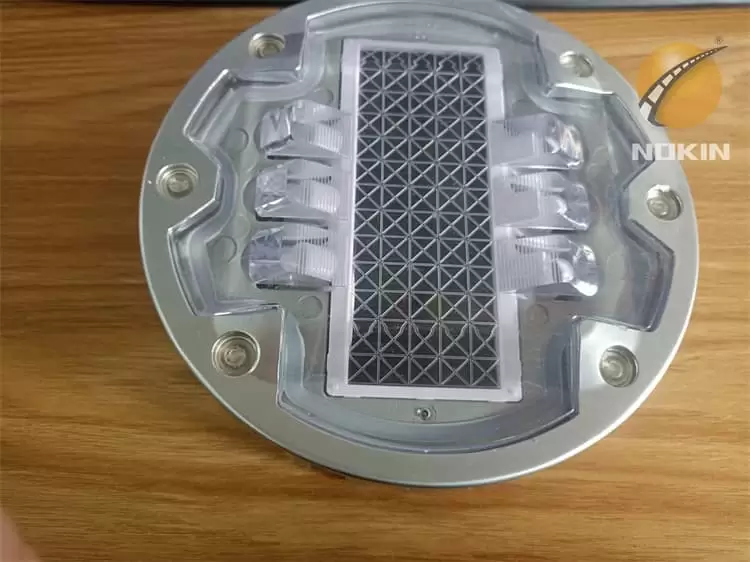

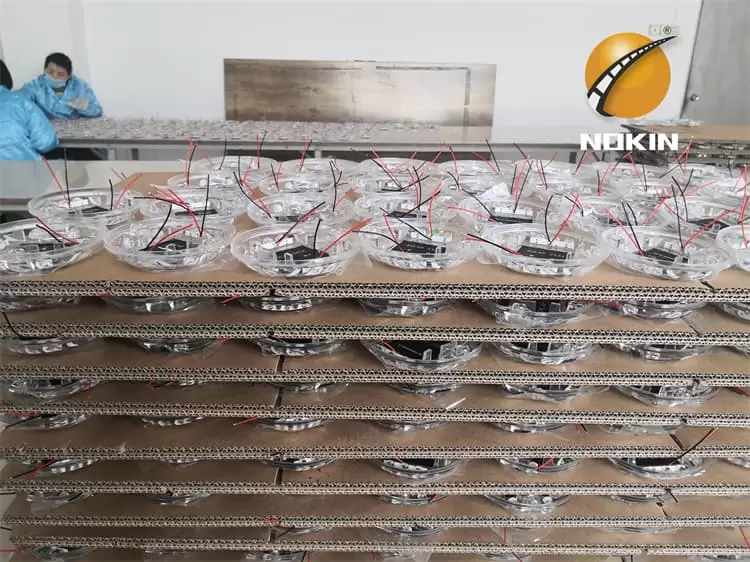

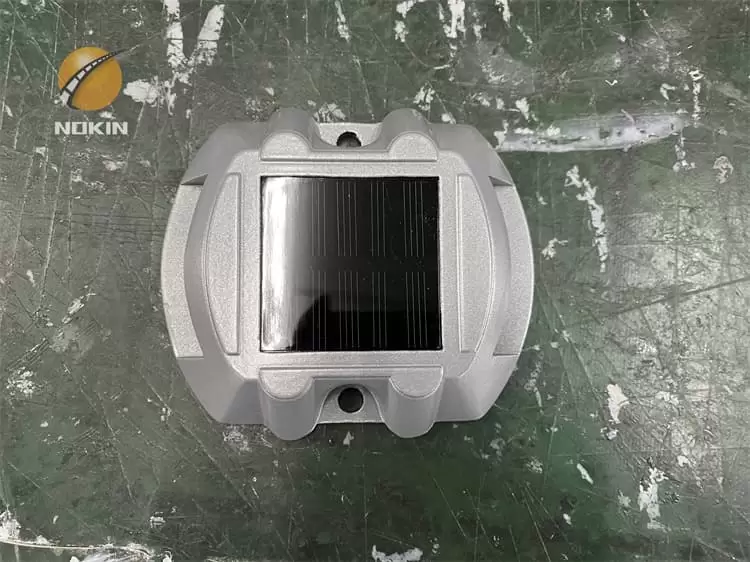

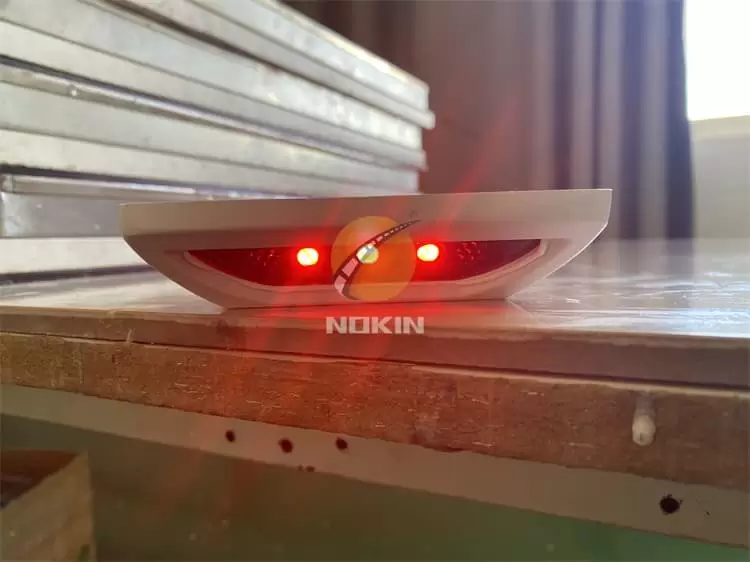

Glue injection plays a pivotal role in the functionality and longevity of solar cat eye road stud lights. By providing sealing, structural integrity, vibration dampening, and thermal management, this process ensures that these lights can withstand the demanding conditions of road environments. The use of specialized adhesives such as epoxy resins and polyurethane further enhances their durability and reliability. As solar road stud lights continue to be a vital component of road safety infrastructure, glue injection remains an essential technique in their manufacturing process, contributing to safer and more sustainable roadways.

Solar road stud lights have revolutionized road safety, offering a sustainable and effective solution for illuminating roadways and improving visibility. These devices are particularly beneficial in marking pathways, intersections, and hazardous areas, ensuring drivers can navigate safely during nighttime or adverse weather conditions. One critical aspect of their construction that ensures durability and functionality is glue injection. This article explores the vital role of glue injection in solar road stud lights, highlighting its importance in maintaining performance and longevity.