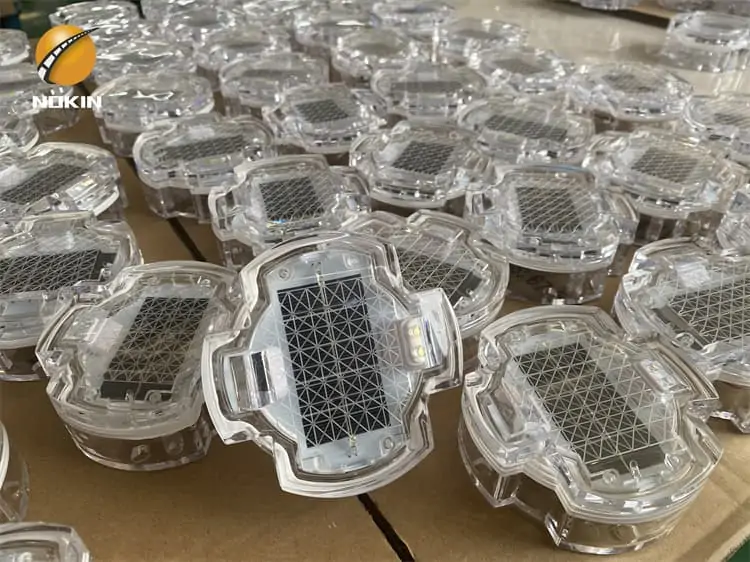

Waterproof Cast Aluminum Solar Road Stud Supplier

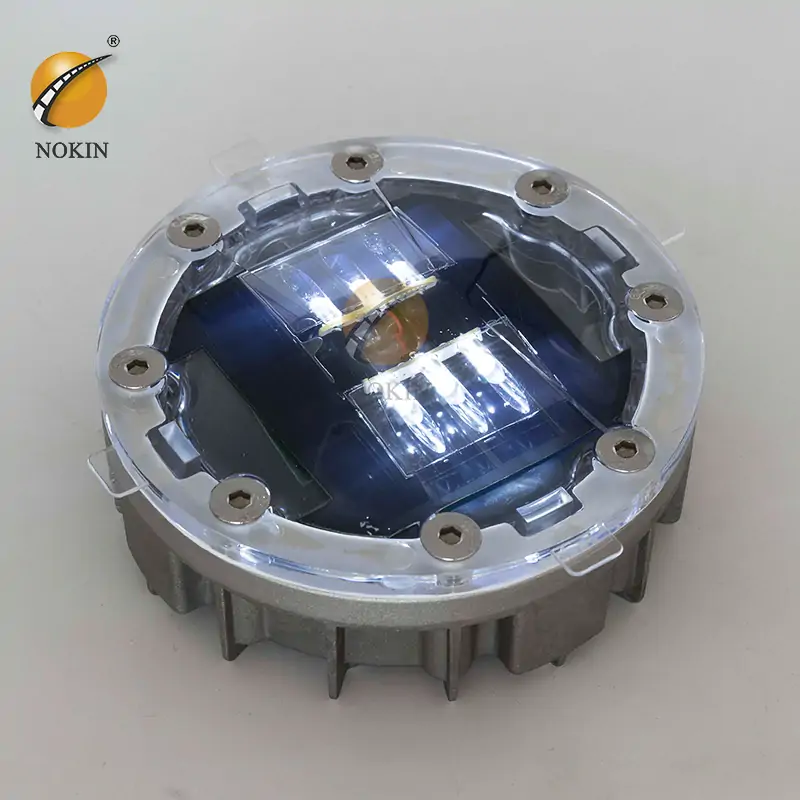

Our LED Solar Powered Road Studs are rated as IP68. They are fully dust-tight and protected from long-term immersion in water. They can withstand up to a specified pressure, and they have limited ingress protection. These lights also come in different colors such as red, green, yellow, white, and blue.

Send Inquiry

Quote Online

Share:

Content

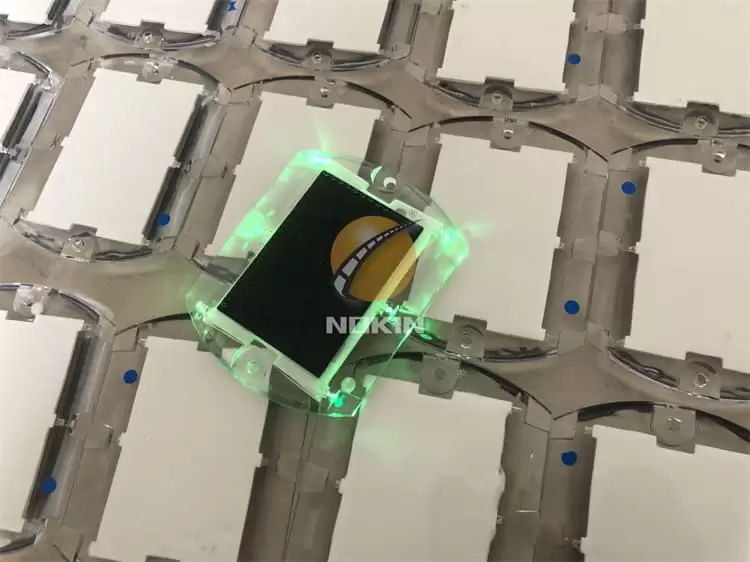

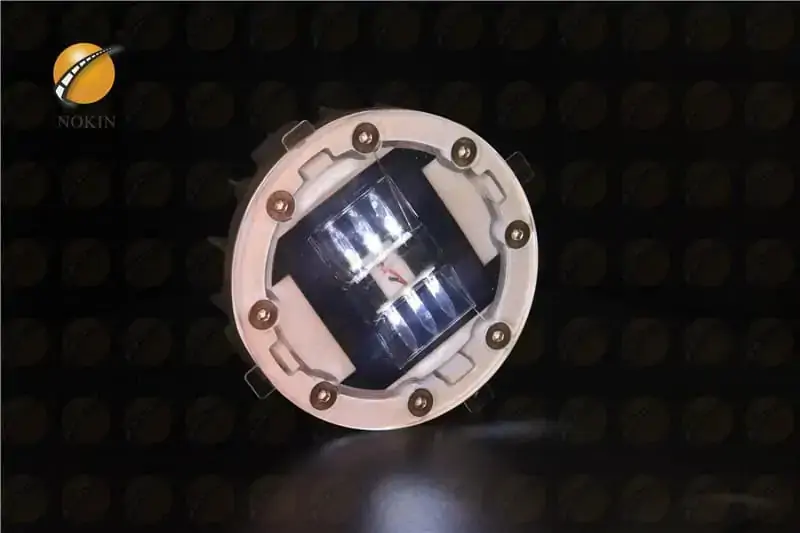

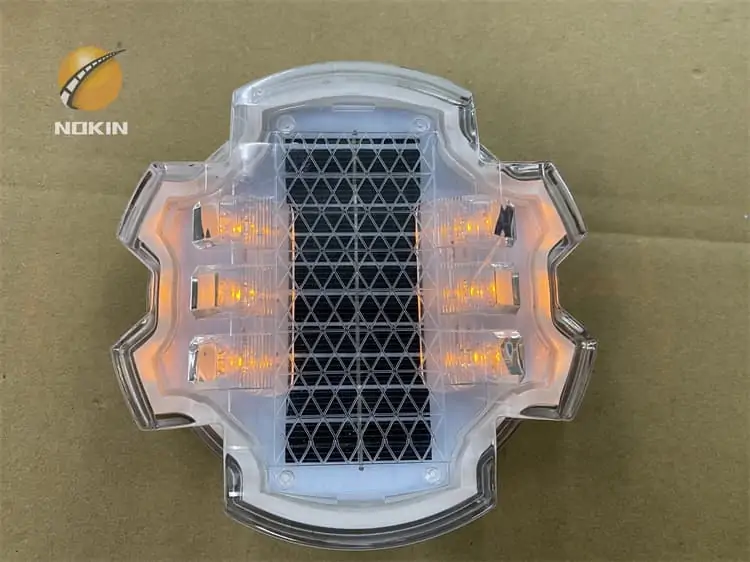

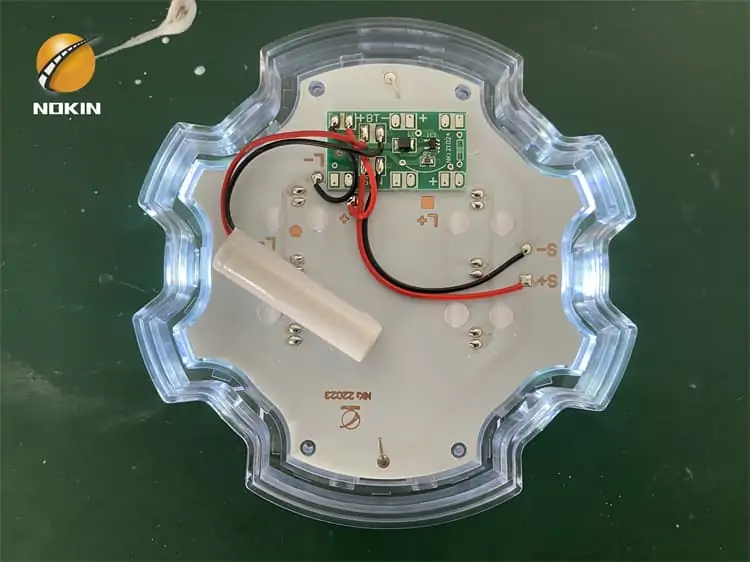

NOKIN offers high-quality LED Solar Powered Road Studs, also known as Road Reflectors. These products are designed to guide vehicles and pedestrians for directions.

The road reflectors we offer are powered by solar energy, making them more environmentally friendly. Because of their light-feeling function, they automatically light up and help guide people on their way.

Our LED Solar Powered Road Studs are rated as IP68. They are fully dust-tight and protected from long-term immersion in water. They can withstand up to a specified pressure, and they have limited ingress protection. These lights also come in different colors such as red, green, yellow, white, and blue.

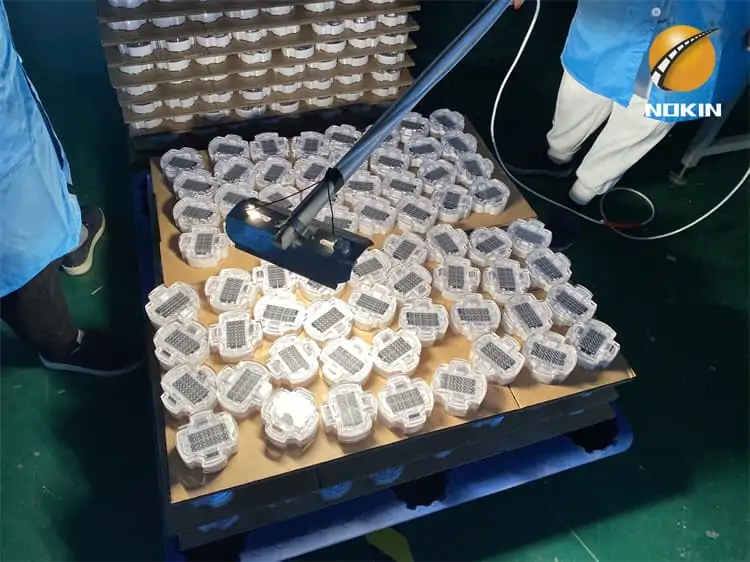

These pieces of lighting equipment signify our commitment to providing quality products to each and every household or business in the Philippines. We continually strive to provide easy access to energy-efficient and environmentally friendly lighting alternatives that are set at reasonably low and affordable prices.

If you need a product recommendation or design inspiration for your projects, you may check out our Completed Lighting Project page for ideas.

For inquiries regarding our products and services, you may also send us an e-mail or contact us through our mobile numbers.

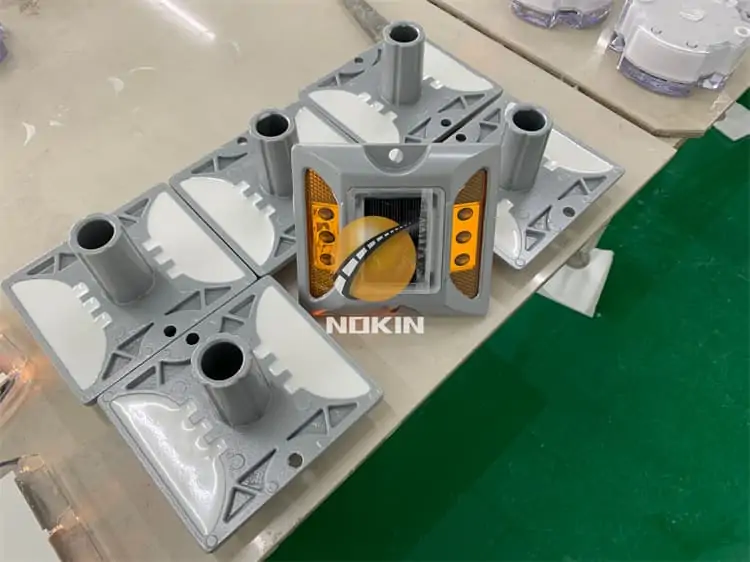

Installation Method Of Raised Solar Road Stud:

Carefully mark the distance between the placement of solar road stud lights. To prevent an adverse effect on the ground, use a proper tool such as Core Drill. Drill 35mm and the depth will be 55mm.

Remove all debris from the installation hole.

Pour epoxy into the holes per the manufacturer’s instruction.

Verify that the installation hole is straight. Verify that the installation hole is large enough to allow the epoxy to surround the solar-led road stud shaft.

Set the lighting surface of the solar road stud to the desired viewing angle. Verify the epoxy is evenly adhering to the installation hole and solar marker shaft. Verify the bottom of the solar road marker is firmly installed on the installation surface allowing for zero surface float; to occur. (space between installation surface and bottom of the solar marker).

After curing the LED solar road stud for 6-8 hours, remove the installation of the isolation facility.

The recommended spacing between each solar road stud is as follows:

Highways and Expressways

7 – 8 yards (5 – 6 meters)

Dangerous Entrances and Exits

4 – 5 yards (2 – 3 meters)

Access or Exit ways for Hospitals, Parking Lots, etc.

0.5 – 3 yards (0.5 – 2 meters)

The spacing between each solar stud is also according to your actual application requirements, the above values are for reference only.

FAQ

Q1: What about the application of the road stud?

A1: Road Delineation, Accident black spots/cluster sites, Hazardous roads, Areas adversely affected by poor visibility, Cycle path, Car parks, Sidelines of highways, roadsides, partition areas, bridge roads, road curves, T-Intersection, highway exits, and many more applications.

Q2.what color do you have?

A2: We have Yellow/white/red/blue/green color

Q3: Can I have a sample order for road studs?

A3: Yes, we welcome sample orders to test and check quality. Mixed samples are acceptable.

Q4: How do you ship the goods and how long does it take to arrive?

A4: We usually ship by DHL, UPS, FedEx, or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping is also optional.

Q5: Is it OK to print my logo on a led light product?

A5: Yes. Please inform us formally before our production and confirm the design first based on our sample.

Q6: Do you offer a guarantee for the products?

A6: Yes, we offer a 2-5 years warranty on our products.

Inquiry

More