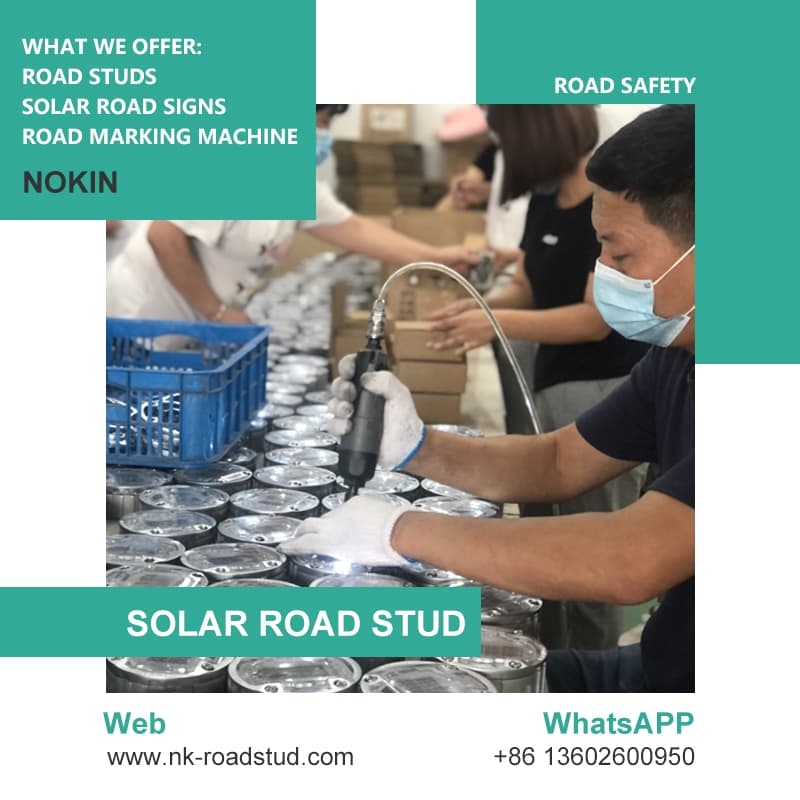

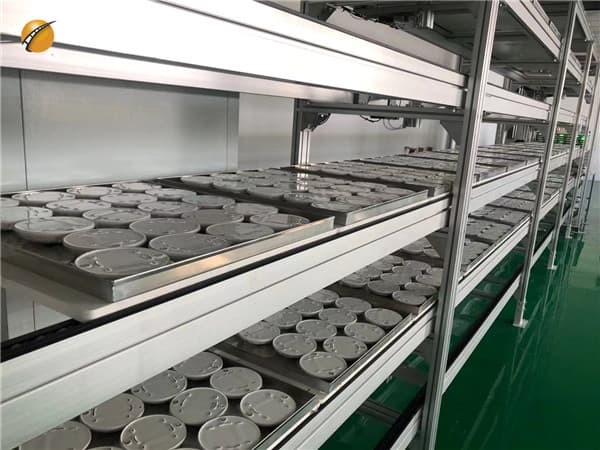

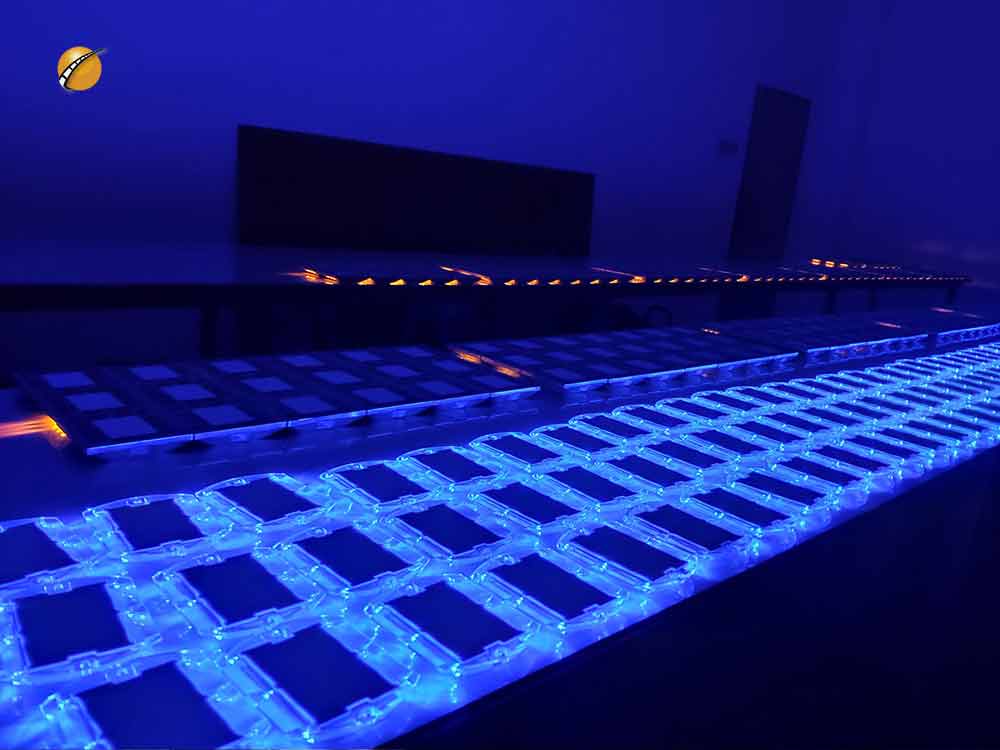

China Solar Road Studs Factory

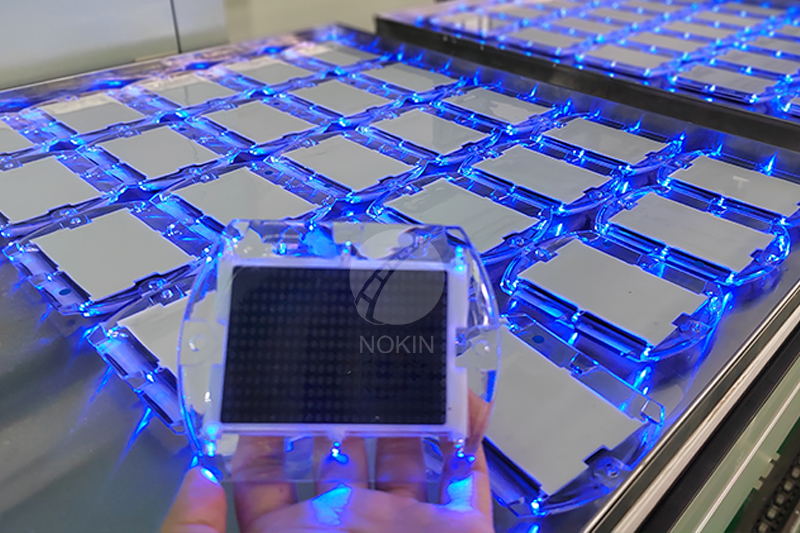

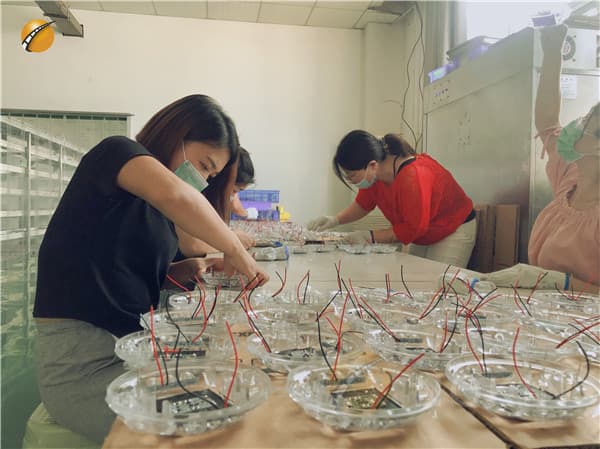

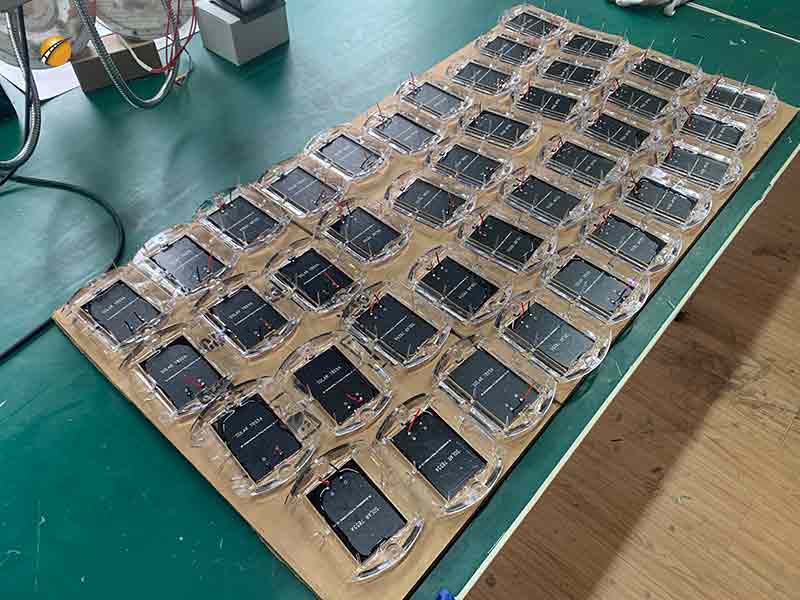

1. Shell material: all aluminum alloy material, the solar material is PC compression material

2. Solar road stud Size: L108mm*W97mm*H25mm

3. Solar panel: Solar panel (mono crystalline 2.5V/0.25W)

4. Solar rechargeable battery: NI-MH 1.2V/800MAH

5. Working environment: -20-+70 degrees

6. Working hours: 8 hours in sufficient light, can be continuously bright for more than 72 hours

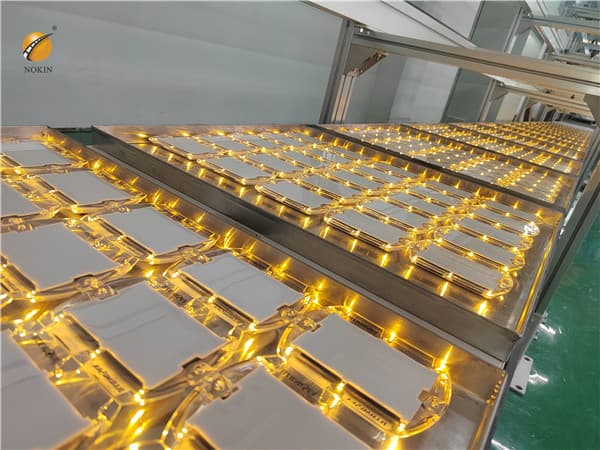

7. Solar road stud Light-emitting mode: flashing or bright

8. LED light color: yellow, red, white, green, blue

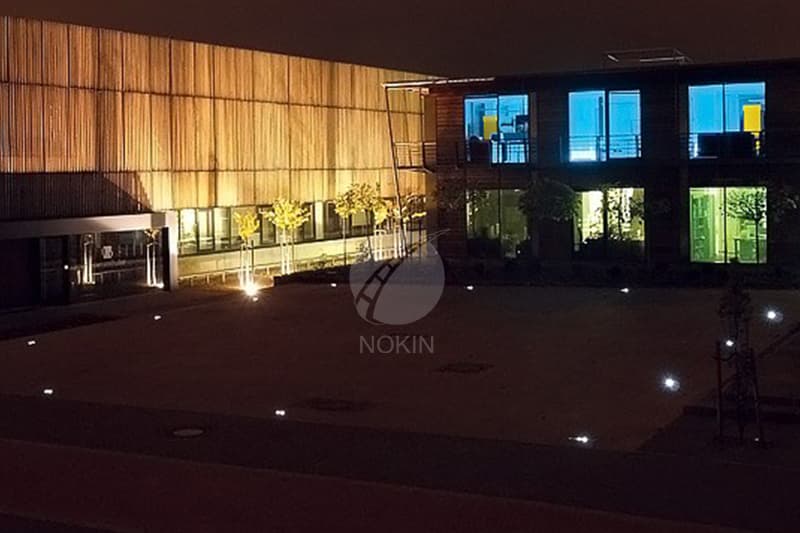

9. Visual distance: more than 800 meters

10. Starting light intensity: 500-700 Lux

11. Compression resistance: greater than 10T

12. Waterproof rating: IP68

Solar road stud installation method:

1. Positioning: First use a ruler to determine the installation position, and ensure that each position is in a straight line longitudinally. The installation distance is subject to the design requirements. The installation place should be flat, dry, clean, and seamless, and the road surface should be washed clean.

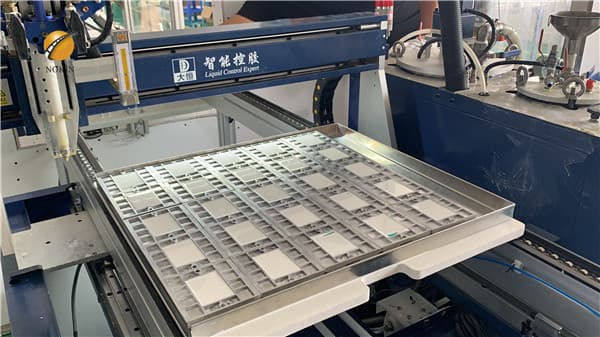

2. Choose a suitable epoxy resin glue, fully mix the glue according to the proportion, and apply the glue on the bottom surface of the spikes. The glue should be moderate, not only stick to the bottom surface of the solar road stud, and not overflow too much, about each solar road stud needs to be used 40-50 grams of glue.

3. Paste the solar road stud on the pre-planned position, press the solar road stud tightly, and fix it.

4. The epoxy resin can be cured after 6 hours, and the road must be sealed for 6 hours to ensure that the glue is cured.